LANGUAGE OF LEAN

Set up time

The term "set up time" refers to the amount of time it takes to transition a manufacturing process or production line from producing one product to another.

The term "set up time" refers to the amount of time it takes to transition a manufacturing process or production line from producing one product to another. This time includes all the tasks and activities that must be performed in order to prepare the line for the new product, such as cleaning and changing tools, adjusting machinery, and organizing raw materials and supplies.

Set up time has its origins in the field of manufacturing, where reducing the time required to change over from one product to another has been a critical factor in improving efficiency and productivity. The idea behind reducing set up time is that the less time a production line is idle, the more products can be produced, and the more efficiently the production process can run.

To improve set up time, organizations can use a variety of methods and techniques. One approach is to standardize set up procedures, so that the same steps are followed every time a change over is performed. This standardization helps to eliminate waste, reduce the risk of errors, and speed up the process.

Another approach is to use technology to automate and streamline set up procedures. For example, a company might use barcode scanning to quickly and accurately identify the right tools and supplies for a particular change over, or use robotic arms to change tools and adjust machinery, reducing the amount of manual labor required.

Organizations can also make use of visual aids, such as standard work instructions, to help workers understand the set up process and complete it more quickly. These instructions can be displayed in the form of checklists, posters, or other visual aids that are easy to understand and follow.

In addition, organizations can work to minimize the number of set ups required by batching products or running them in a continuous flow, which reduces the need to change over production lines as frequently.

Finally, it is also important to involve workers in the process of improving set up time. By engaging workers in the process and soliciting their input and suggestions, organizations can gain valuable insights into how the process can be improved and find new and innovative ways to reduce set up time.

In conclusion, improving set up time is critical for organizations that want to optimize their production processes and improve efficiency. By using a combination of standardization, technology, visual aids, continuous flow, and worker involvement, organizations can reduce set up time, minimize waste, and improve productivity

Hoshin Kanri Catchball

The Hoshin Kanri Catchball Process is a key component of Hoshin Kanri methodology and is used to facilitate communication and collaboration between different levels of the organization.

Hoshin Kanri, also known as Policy Deployment, is a strategic planning and management methodology originating from Japan. The methodology is designed to align an organization's strategic goals with its daily operations and decision-making processes. The Hoshin Kanri Catchball Process is a key component of this methodology and is used to facilitate communication and collaboration between different levels of the organization.

The Hoshin Kanri Catchball Process involves four phases:

Phase 1: Setting Strategic Objectives

The first phase of the Hoshin Kanri Catchball Process is setting strategic objectives. This involves the top management of the organization setting the company's overall vision and direction for the coming year. The objectives should be specific, measurable, and achievable.

Phase 2: Creating an Action Plan

Once the strategic objectives have been set, the next phase is to create an action plan for achieving them. This involves breaking down the objectives into smaller, measurable goals and identifying the specific actions that will be taken to achieve each goal. The action plan should be communicated to the rest of the organization and reviewed regularly to ensure that progress is being made towards achieving the goals.

Phase 3: Implementing and Monitoring the Plan

The third phase of the Hoshin Kanri Catchball Process is the implementation and monitoring of the action plan. This involves communicating the goals and action plan to the rest of the organization and ensuring that everyone is working towards the same objectives. It also involves regular progress updates and reviews to ensure that the plan is on track.

Phase 4: Continuously Improving

The final phase of the Hoshin Kanri Catchball Process is the continuous improvement phase. This involves reviewing the results of the action plan and making adjustments as necessary to ensure that the organization's objectives are being met. The continuous improvement phase is a critical component of the Hoshin Kanri methodology, as it helps to ensure that the organization is always making progress towards its goals.

The Hoshin Kanri Catchball Process is called "catchball" because it is designed to involve all levels of the organization in the communication and collaboration process. The process is based on the idea of "catching" the ball and passing it back and forth between different levels of the organization. This creates a culture of continuous improvement, as everyone in the organization is involved in the process and working towards the same goals.

The best way to implement the Hoshin Kanri Catchball Process is to adopt it as a company-wide system and involve all employees in the process. This involves:

Clearly communicating the company's strategic objectives and action plan to everyone in the organization.

Encouraging all employees to participate in the continuous improvement process by providing regular training and development opportunities.

Regularly monitoring progress and making adjustments to the action plan as necessary.

Celebrating successes and sharing best practices with others in the organization.

Continuously reviewing the results of the Hoshin Kanri Catchball Process and making improvements as necessary to ensure that it remains an effective tool for achieving the company's goals.

It is also important to have a clear understanding of the Hoshin Kanri methodology and the Catchball Process, as well as the tools and techniques used to implement it, such as Hoshin Planning, X-Matrix, and A3 Problem Solving. Regular training and development opportunities for employees can help to ensure that everyone in the organization is equipped with the skills and knowledge needed to effectively participate in the process.

In conclusion, the Hoshin Kanri Catchball Process is a powerful tool for aligning an organization's strategic objectives with its daily operations and decision-making processes. By involving and empowering all employess to join the process.

Hoshin Kanri

Hoshin Kanri, also known as Policy Deployment, is a strategic planning and management methodology originating from Japan

Hoshin Kanri, also known as Policy Deployment, is a strategic planning and management methodology originating from Japan. The term "Hoshin" means "compass" or "direction," and "Kanri" means "management." Hoshin Kanri is a system that aligns an organization's strategic goals with its daily operations and decision-making processes.

Hoshin Kanri was first developed in the late 1950s and 1960s at the Japanese automobile manufacturer Toyota and is often associated with the Lean Management philosophy. It was introduced as a way to ensure that the company's long-term goals were being pursued throughout the organization, from top management to the shop floor. The methodology has since been adopted by many other companies and industries, including manufacturing, healthcare, government, and service organizations.

Hoshin Kanri is a cyclical process that involves four main steps:

Setting strategic objectives: The first step in Hoshin Kanri is to set the organization's strategic objectives for the coming year. This is typically done by top management, who establishes the company's overall vision and direction.

Creating an action plan: Once the strategic objectives have been set, the next step is to create an action plan for achieving them. This involves breaking down the objectives into smaller, measurable goals and identifying the specific actions that will be taken to achieve each goal.

Implementing and monitoring the plan: The third step is to implement and monitor the action plan. This involves communicating the goals and action plan to the rest of the organization and ensuring that everyone is working towards the same objectives. Regular progress updates are made to ensure that the plan is on track.

Continuously improving: The final step in the Hoshin Kanri process is to continuously improve. This involves reviewing the results of the action plan and making adjustments as necessary to ensure that the organization's objectives are being met.

One of the key features of Hoshin Kanri is that it promotes a culture of continuous improvement by involving all employees in the process. By aligning the company's daily operations with its long-term goals, Hoshin Kanri helps to ensure that everyone in the organization is working towards the same objectives and that progress is being made towards achieving them.

The best way to utilize Hoshin Kanri is to adopt it as a company-wide system and involve all employees in the process. This involves:

Clearly communicating the company's strategic objectives and action plan to everyone in the organization.

Encouraging all employees to participate in the continuous improvement process by providing regular training and development opportunities.

Regularly monitoring progress and making adjustments to the action plan as necessary.

Celebrating successes and sharing best practices with others in the organization.

Continuously reviewing the results of the Hoshin Kanri process and making improvements as necessary to ensure that it remains an effective tool for achieving the company's goals.

In a nutshell, Hoshin Kanri is a powerful tool for aligning an organization's strategic objectives with its daily operations and decision-making processes. By involving all employees in the process, it helps to ensure that everyone is working towards the same objectives and that progress is being made towards achieving them. To get the most out of Hoshin Kanri, it is important to adopt it as a company-wide system and continuously review and improve the process.

Ringi Seido

The Ringi Seido methodology that originates from Japan is widely recognized as an effective method for achieving operational excellence in decision making.

The Ringi Seido methodology that originates from Japan is widely recognized as an effective method for achieving operational excellence. As an operational excellence expert, I can attest the benefits of implementing Ringi Seido in your organization.

Ringi Seido, which translates to "approval process," is a consensus-based decision-making system that involves different levels of an organization in the decision-making process. It is considered an essential element of Japanese business culture and has been widely adopted by Japanese companies for decades.

One of the key principles of Ringi Seido is involving all relevant stakeholders in the decision-making process. This includes front-line employees, middle management, and executives, allowing for a comprehensive and well-rounded approach to decision-making. The goal is to gain buy-in from all levels of the organization and ensure everyone is aligned with the company's vision and direction.

The Ringi Seido process begins with a proposal for a change or new initiative, which is then shared and discussed among the relevant stakeholders. Through a series of meetings and discussions, the proposal is refined and modified until it has the support of all relevant stakeholders.

One of the key benefits of the Ringi Seido process is that it ensures all necessary information is considered before a decision is made. This helps to reduce the risk of making decisions that are not in the best interests of the organization. Additionally, the process provides the opportunity for employees to voice their opinions and share their ideas, which can lead to the discovery of new and better ways of doing things.

Another benefit of Ringi Seido is that it promotes a culture of continuous improvement. The process encourages employees to regularly review and evaluate the implementation of the approved initiatives, which allows for the identification of areas that need improvement. This leads to a continuous cycle of improvement, as the organization continuously refines its processes and procedures to achieve better results.

One of the challenges of implementing Ringi Seido is that it can be time-consuming and require significant investment in training and development opportunities for employees. However, the benefits of the methodology make it a worthwhile investment, as it can lead to significant improvements in the efficiency and effectiveness of an organization's operations.

For organizations that are interested in implementing Ringi Seido, it is essential to have a clear understanding of the methodology and the specific steps involved in the approval process. This requires the participation of all relevant stakeholders and a commitment from the organization to provide the necessary resources, including training and development opportunities, to ensure the successful implementation of the methodology.

In a nutshell, I highly recommend the implementation of Ringi Seido for organizations looking to achieve operational excellence. While it may require a significant investment in time and resources, the benefits of the methodology make it a powerful tool for achieving better results. By involving all relevant stakeholders in the decision-making process, organizations can gain buy-in from all levels of the organization and ensure everyone is aligned with the company's vision and direction. This leads to a culture of continuous improvement, which is essential for achieving long-term success.

Push Principle

The Push Principle Concept/Term refers to a production system where material and products are manufactured and moved along the production line based on a predicted demand, rather than actual demand.

The Push Principle Concept/Term refers to a production system where material and products are manufactured and moved along the production line based on a predicted demand, rather than actual demand. This system operates under the assumption that the customer demand can be accurately forecasted and the production line can be appropriately scheduled to meet that demand.

However, the Push Principle often leads to negative impacts on operations. One of the main problems with this system is the assumption of accurate demand forecasting. In reality, customer demand is highly unpredictable and can fluctuate rapidly, leading to overproduction and inventory buildup. This excess inventory creates significant problems such as storage and handling costs, obsolescence, and potential quality issues.

Additionally, the Push Principle often results in an inefficient utilization of resources. The production line is designed to produce a set amount of product, regardless of actual demand. This can lead to idle time and equipment, increased energy costs, and reduced production capacity. The production process is also disrupted by production line breakdowns, worker absences, and equipment failures, resulting in increased downtime and decreased efficiency.

Another negative impact of the Push Principle is that it can lead to a lack of focus on customer needs. The emphasis is on meeting a predetermined production schedule, rather than meeting the actual needs of the customer. This can result in an overproduction of products that are not needed, as well as a lack of flexibility to adapt to changing customer demand.

To mitigate these negative impacts, Lean Management experts advocate for the implementation of the Pull Principle. The Pull Principle is a system where production is based on actual customer demand, rather than a predicted demand. This system allows for a more flexible and efficient utilization of resources, as well as a greater focus on meeting the actual needs of the customer.

In a nutshell, the Push Principle can lead to negative impacts on operations such as inventory buildup, resource inefficiency, and a lack of focus on customer needs. Lean Management experts recommend the implementation of the Pull Principle as a more efficient and effective alternative. By focusing on actual customer demand, organizations can achieve greater operational efficiency and meet the needs of their customers.

Bullwhip Effect

The bullwhip effect is a well-known phenomenon in lean management that can have a significant impact on the push and pull principles of supply chain management.

The bullwhip effect is a well-known phenomenon that can have a significant impact on the push and pull principles of supply chain management. The bullwhip effect refers to the amplification of demand fluctuations as they move up the supply chain, leading to increased inventory, increased costs, and decreased customer satisfaction.

The bullwhip effect is caused by a number of factors, including demand forecast errors, order batching, price fluctuations, and the use of incentives that encourage suppliers to order more than they need. These factors can cause suppliers to overreact to demand changes, leading to excessive inventory levels and higher costs.

The impact of the bullwhip effect on the push and pull principles of supply chain management can be significant. The push principle is based on the idea that suppliers produce goods based on demand forecasts, and then push the goods to the customer. The bullwhip effect can cause demand forecasts to become less accurate, leading to increased inventory levels, increased costs, and decreased customer satisfaction.

The pull principle, on the other hand, is based on the idea that suppliers produce goods based on actual customer demand. The bullwhip effect can cause suppliers to overreact to demand changes, leading to increased inventory levels and higher costs. This can result in a situation where suppliers are producing goods that are not actually needed, leading to a decrease in customer satisfaction and increased waste.

To address the bullwhip effect, organizations can implement a number of strategies, including improving demand forecasting accuracy, reducing order batching, reducing price fluctuations, and using incentives that encourage suppliers to order what they need, when they need it.

One approach to reducing the bullwhip effect is to implement a demand-driven supply chain management system. This involves using real-time data to better understand customer demand, and using this information to make informed decisions about inventory levels and production schedules. This can help to reduce the bullwhip effect, leading to more accurate demand forecasts, lower inventory levels, and increased customer satisfaction.

Another strategy to address the bullwhip effect is to implement a lean supply chain management system. This involves reducing waste, streamlining processes, and improving communication and collaboration between suppliers, manufacturers, and customers. This can help to reduce the bullwhip effect, leading to improved supply chain efficiency, lower costs, and increased customer satisfaction.

In a nutshell, the bullwhip effect is a well-known phenomenon in lean management that can have a significant impact on the push and pull principles of supply chain management. To address the bullwhip effect, organizations can implement a number of strategies, including improving demand forecasting accuracy, reducing order batching, reducing price fluctuations, and using incentives that encourage suppliers to order what they need, when they need it. By implementing these strategies, organizations can reduce the bullwhip effect, leading to more accurate demand forecasts, lower inventory levels, and increased customer satisfaction.

JIT

Just-in-Time (JIT) is a manufacturing and inventory control system in which raw materials, components, and finished products are delivered to the production line exactly when they are needed.

Just-in-Time (JIT) is a manufacturing and inventory control system in which raw materials, components, and finished products are delivered to the production line exactly when they are needed. The goal of JIT is to minimize inventory levels and reduce lead times, while maintaining high levels of production efficiency.

JIT is a pull-based system, which means that production is driven by customer demand rather than by a production schedule. This is achieved by using Kanban, a signaling system that alerts the supplier to send more materials or components when the inventory level of a specific item reaches a predetermined minimum level.

The origins of JIT can be traced back to the manufacturing practices of the Toyota Motor Company in the 1950s. It was developed by Taiichi Ohno, an engineer at Toyota, as a response to the inefficiencies he observed in the company's production processes. Ohno recognized that by reducing the amount of inventory and increasing the flow of materials, Toyota could improve its production efficiency and responsiveness to customer demand.

One of the key principles of JIT is the elimination of waste, or "muda" in Japanese. Ohno identified seven types of waste in manufacturing: overproduction, waiting, unnecessary motion, overprocessing, defects, excess inventory, and unused human potential. JIT aims to eliminate these forms of waste by creating a smooth and efficient flow of materials and products through the production process.

JIT also relies on the concept of "one piece flow", which is the production of one item at a time, rather than producing large batches of items. This allows for better control of the production process, as well as the ability to quickly identify and correct any problems that may arise.

Another important aspect of JIT is the use of visual management tools, such as Andon boards and Kanban boards. These tools allow for real-time monitoring of the production process, and can alert workers to potential problems before they become major issues.

JIT also requires a high level of collaboration and communication between suppliers, manufacturers, and customers. This is necessary to ensure that materials and components are delivered to the production line exactly when they are needed, and that finished products are delivered to customers in a timely manner.

JIT has a number of benefits for manufacturers. One of the most significant is that it can help to reduce inventory levels, which can free up valuable floor space, reduce storage costs, and minimize the risk of stockouts. JIT can also help to improve production efficiency by reducing lead times and minimizing downtime caused by waiting for materials or components.

JIT can also help to improve product quality by reducing defects, and increasing the ability to quickly identify and correct any problems that may arise in the production process.

JIT also helps companies to be more responsive to customer demand by reducing lead times and increasing the speed of delivery. This can help to improve customer satisfaction, and increase the chances of repeat business.

JIT also helps companies to be more flexible and adaptable to changes in customer demand. It allows companies to more easily shift production to different products or product lines, which can help to maintain profitability during periods of slow sales.

However, it's worth noting that JIT is not suitable for all industries and companies, it's best applied in companies where the production process is well-defined, the demand is stable and predictable, and the lead times are short. Implementing JIT can also be challenging and requires a significant investment of time and resources to establish an effective system.

Additionally, JIT requires a high level of coordination and communication with suppliers and customers, which can be difficult to achieve. This is particularly true for companies that have a large number of suppliers or customers, or those that operate in

KOSU

KOSU, short for "Key Operating System Units", is a method used in Lean management and operational excellence to identify and measure the critical units of a process that are essential for the overall performance and success of the operation.

KOSU, short for "Key Operating System Units", is a method used in Lean management and operational excellence to identify and measure the critical units of a process that are essential for the overall performance and success of the operation. By identifying these key units, organizations can focus their improvement efforts on the areas that will have the greatest impact on performance.

The basic idea behind KOSU is to identify the critical units of a process that are essential for the overall performance and success of the operation. This can include things like machines, equipment, personnel, and processes. By identifying these key units, organizations can focus their improvement efforts on the areas that will have the greatest impact on performance.

One of the key benefits of using KOSU is that it helps organizations to identify and prioritize the areas of the process that are most critical to performance. By identifying the key units of a process, organizations can focus their improvement efforts on those areas that will have the greatest impact on performance. This allows them to make the most of their resources and achieve the greatest return on investment.

Another benefit of using KOSU is that it helps organizations to identify and eliminate bottlenecks in the process. By identifying the key units of a process, organizations can identify which units are causing delays and bottlenecks in the process, and then take action to eliminate those bottlenecks. This can include things like improving machine maintenance, optimizing production processes, or identifying areas where automation can be used to improve efficiency.

Using KOSU also helps organizations to identify areas where standardization can be used to improve a process. By identifying the key units of a process, organizations can identify which units are taking longer than they should, and then take action to standardize those processes. This can include things like implementing best practices, developing standard operating procedures, or identifying areas where automation can be used to improve efficiency.

In addition, KOSU can be used to identify areas where automation can be used to improve efficiency. By identifying the key units of a process, organizations can identify which units are taking longer than they should, and then take action to automate those processes. This can include things like using robotics, using automated inspection systems, or using artificial intelligence to optimize production processes.

KOSU also plays a critical role in analyzing machine’s capacity. By identifying the key units of a process, organizations can identify which units are operating at full capacity, and which ones have room for improvement. This can help organizations to optimize their production processes, and ultimately, increase their overall production capacity.

In a nutshell, KOSU is a powerful method for organizations that are committed to operational excellence and continuous improvement. By identifying the key units of a process, organizations can focus their improvement efforts on the areas that will have the greatest impact on performance, eliminate bottlenecks in the process, use standardization to improve a process, use automation to improve efficiency and increase their overall production capacity.

Kanban

The material in the Kanban System is exclusively oriented to the consumption of your production process.

In this article we want to talk about another classic from Lean Management Kanban or the so called Pull System.

The word Kanban itself has its roots in the Chinese Japanese language and means card, label or sticker. In industrial manufacturing planning systems or general in logistics control Kanban describes a replenishment system for consumed parts according to the amount used steered by cards that give the signal following the Pull Principle.

The material in the Kanban System is exclusively oriented to the consumption of your production process. The cards are a key element of this kind of control system and provide proper information transfer. Kanban control loops from the work station of flexible production control and serves to smooth material flow through your inbound or even outbound logistics. In addition Kanban serves you to implement a sustainable reduction of material stocks, increases the ability to deliver and saves you pure cash.

In an ideal world Kanban would control your entire value chain from the supplier to the end customer. In this way you would have installed an complete smooth supply chain with almost no chance of interruption and massive stocks. And now comes the but – to steer production with Kanban – a continuous monitoring is required for a smooth material supply. To make it short: it requires discipline from all involved parties along the supply chain.

Lets have a look to the development of Kanban.

The first Kanban System was developed by none other than Taiici Ohno (of course) at Toyota Motor in the 1940s. One of the main reasons for the implementation of Kanban was the low productivity and efficiency of Toyota compared to western competitors. With the Kanban System, Toyota achieved a significant change towards flexible and efficient production control that had a massive impact on productions output while at the same time reducing the costs for inventory in raw material, work in progress (WIP) and finished goods.

To give the complete picture it wasn’t implementing the Kanban system itself to drive the success of Toyota, there are other key factors that together where making the difference. Just to name Just in time as an example of key elements of the Toyota Production System. It is and always will be a combination of different methods and philosophy that brings you forward.

In the 1970s the Kanban Concept was adapted in the industry in the USA and Germany. As they haven’t known better, they pretty much copied the complete Toyota Production System (TPS) in order to get the principles running.

Pull or Kanban System

Either way you call it, the material flow is controlled by boxes or cards. Kanban Cards serving in a simple way all information needed to identify what parts are needed in what quantity at what place. The amount typically is defined by the replenishment time at the work station. With the so called two box principle you make sure that the operator never runs short on components. Nowadays there are also digital version of it called eKanban, but the principle behind is the same. The trigger of supply is the Kanban Card starting of the pull chain of material.

To use Kanban efficient, it is not suitable for all parts. Kanban is perfect for small parts with a small amount of variants and a consistent demand. For this reason, you’ll see Kanban Systems in the industry mostly used for C-Parts management. The rest of the components are steered with the support of MRP. Only in rare cases you find that even the supply of big components are controlled with the Kanban methodology.

One nice side effect with Kanban, you can set up the way you can steer your bottleneck. That means, when you have done a proper value stream analysis you know the capacity for your bottleneck and will only order what this process step can handle.

Poka Yoke

Poka Yoke are all mechanisms that prevent unplanned mistakes from happening.

Poka-Yoke is any mechanism that helps to avoid unplanned mistakes. Poka-Yoke is that the application of straightforward, error-proof mechanisms to systematically avoid incorrect assembly, mix-ups or the downstream movement of defective parts. As a result of stable and high-quality methods begin long before the assembly section, simple Poka-Yoke measures will be enforced preventively within the construction and coming up with phase to make sure quality. Poka-Yoke is implemented to avoid: going away out or forgetting process steps, process or operational-related mistakes, incorrect or missing parts, setup or installation errors.

POKA YOKE ポカヨケ ("stupid mistakes - avoidance") is associate ideology that takes a spread of approaches to optimize production processes, particularly assembly. The main target of Poka-Yoke is strive for zero-defect production and to attain it approximately. If defects are detected, the cause is determined. If the cause can be avoided, it's eliminated pretty much as good as doable within the sense of Poka-Yoke and at the best doesn't occur again at all. Poka-Yoke was originally an initiative of Dr. Shingo, Shigeo (新郷 重夫), who is additionally a co-founder of the Toyota production system, of that Poka-Yoke is a core component. Poka-Yoke is beneath the umbrella of Kaizen 改善 ("continuous improvement for the better").

Poka-Yoke may be about recognizing the root causes in time and so eliminating them. Mistakes shouldn't solely be corrected, however prevented the in the longterm by eliminating their root causes. Within the ideal case, in the sense of Poka-Yoke, there are measures that utterly rule out a discovered error by eliminating the cause in the future, e.g. as a result of incorrect mounting is not any longer doable because of fixed given mounting ways (e.g. fitting shapes). Poka-Yoke demands product style ability to make a product design that forestalls errors (avoid incorrect operation) and is powerful against errors (despite incorrect operation no faulty processes). Thus the philosophy of Poka-Yoke doesn't solely begin within the production, however already in the product design.

A widely known everyday example is that the plug of the electric devices and the power outlets, that can't be inserted into the socket the incorrect way round. Measuring instruments may also be designed or programmed in such a way that they will not be misused. Poka-Yoke principles can also be found in other cases, e.g. ATMs dispense your credit card before the payout takes place. Fuel dispenser faucets solely work into the right tank for diesel or petrol, creating it tougher to refuel incorrectly. And so on.

Looking at Poka-Yoke in production "Nobody makes any mistakes" is the target of the Poka-Yoke methodology. Here a list of some mistakes that can typically be found in production:

Incorrect positioning of assembly components

Incorrect change of a die

Incorrect mounting

Wrong interpretation of directions

Incorrect polarity in electrical connections

Incorrect reading of measured values

Incorrect connection of hoses

Incorrect entries in devices

Assembly of wrong components

Skipped operations

Operation/programming errors on machines

POKA YOKE follows three simple steps

Measurement:

If you can’t measure you can’t control. Simple fixtures or sensors up to high performance camera systems can support the right execution of processes and provides feedback about the correct or incorrect task completion. Measures can be taken by cameras, mechanical, sensor for light and colors, position, vibration, voltage or temperature.

Detection of deviation:

E.g. deviations are determined by checking the amount of tasks done during one operation - has had the operator enough movement to do the job? Are enough components used? (actual-target comparison). Or simple exploitation geometric mismatches when pins or special marking at the workstation are still visible or not used.

Regulation

When deviations occur make sure that measures are taken such as pulling the ANDON CORD by the so called stop the line authority. Only when error-causing steps are cancelled out a permanent production of OK parts can be achieved.

Only when living according to the Poka-Yoke philosophy on a daily basis and following the principles of Poka-Yoke you will be able to achieve with smart automation and trained operators long term success. Root Cause Analysis and sustainable counter measurements are key. In addition each operator should be trained to detect their own faults during operation.

It might seam to be waste to train operators to detect failures, but no matter how much you planing and effort you put in design, failures occur during assembly or manufacturing. Just think about wiring that is now crossing moving components, parts where the collision was not seen during design and so on, trust me the list can be endless. Some failures will be detected with smart automation checking devices. But these are typically very costly and need special trained people to maintain and most of the time these little pieces of technology can only do one job. Here joins Poka-Yoke the game. Cost efficient, failures or incorrect assemblies can’t be passed on and each operator develops an eye for deviation.

Just keep in mind that if you have mass production or small to middle series can determine if you should install a 100% check or if simple Poka-Yokes can get you where you want.

The most important part of Poka-Yoke at all is that failures are detected when they occur and the exponentially rising costs of defective parts passed on are prevented.

Value Creation

What the customer is willing to pay for.

The exact opposite of waste is value creation. That is what you aim for with all lean activities. Value creation are all activities that create or add value to your service or product and the customers are willing to pay for. When a service or product has been perceived or appraised to fulfill a customer need or desire as defined, the product or service may be said to have value or worth. Components of value may include quality, utility, functionality, capacity, aesthetics, timeliness or availability, price, etc.

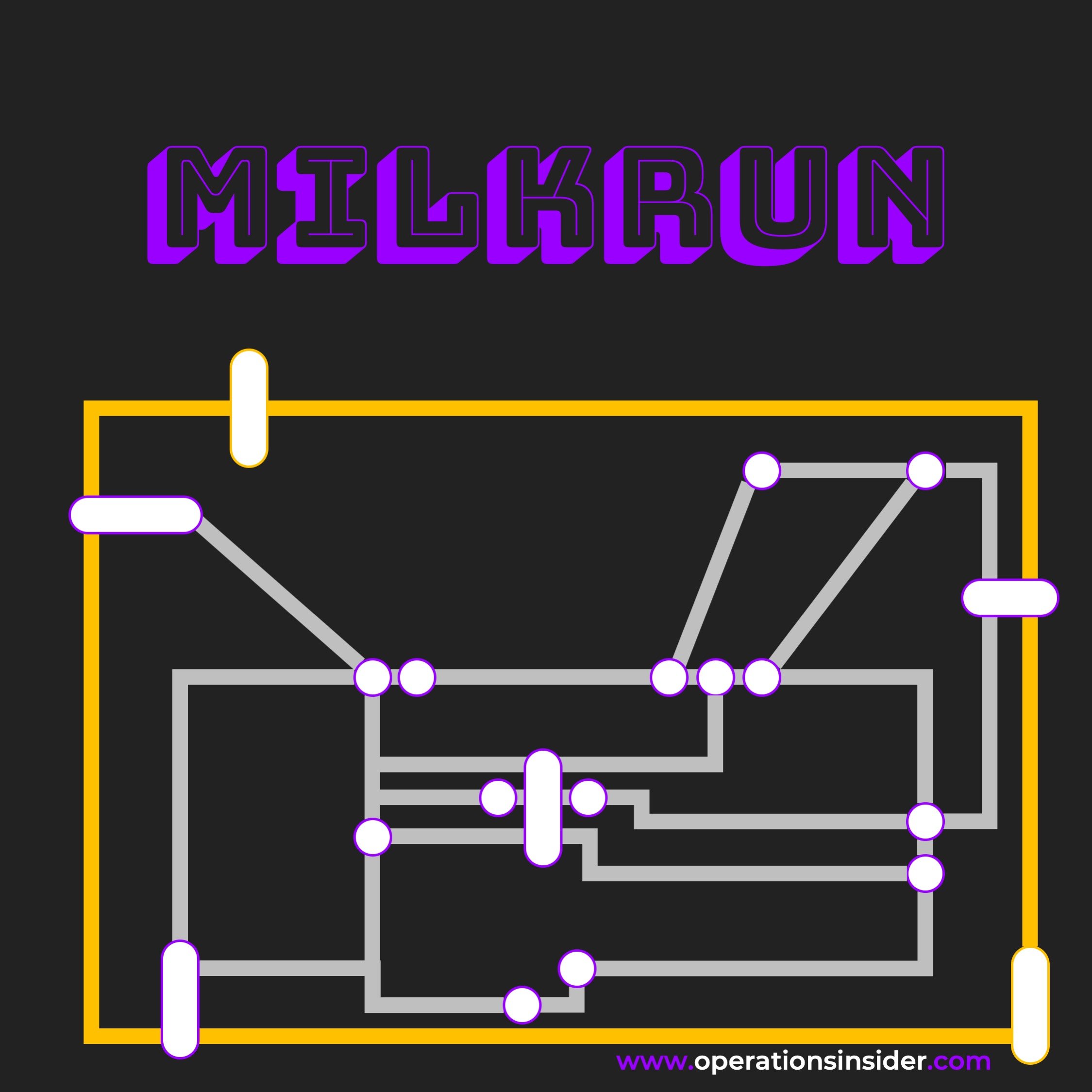

Milkrun

The Milkrun is the preset intralogistics concept to bring raw material, semi finished and finished goods to the place they belong at the time they are needed.

The Milkrun is the preset intralogistics concept to bring raw material, semi finished and finished goods to the place they belong at the time they are needed. The Mikrun is implemented based on existing consumption values, an internal supply cycle is defined in which deliveries on fixed routes are installed with specific times.

Based on these current consumption values, a logistic supply cycle is defined wherein raw material, semi and finished goods are delivered and picked up by a fixed route at a specific time. With this you will also optimize your intralogistics concept in general taking on action for a Milkrun concept.

So what is the idea behind the Milkrun concept.

The term Milkrun comes from the traditional milkman that was supplying milk to homes on a fixed route in a specific time. The milk delivery was based on the consumption of the households, by this only the amount of milk needed was delivered. Empty bottles have been picked up at the same time and brought back to the distribution center. So quite simple full bottle(s) delivered, empty bottle(s) picked up.

The cross company Milkrun

Nowadays the material management got a little bit more complex. Speaking in the external way of logistics a Milkrun is a supplier concept where customers ask for one or more shipping companies to manage different suppliers or customers on after the other in the form of a shipping cycle. In this way, goods and empty containers can be delivered and received at the same time without the need of centralization. The main goal is to have as less as possible empty trucks and at the same time being under full control of external material flow. Tours and deadlines are the guard rails on these cycles, reducing storage space is the nice to have side effect.

The benefits of the Milkrun concept

With installing a Milkrun you will be able to reduce shipping times, processing processes and therefore handling costs.

Just in Time and Just in Sequence deliveries are possible

Your planning is more structured as you will have fixed time frames

Less capital needed due to decreasing inventory/stock/WIP

You can integrate waste and empty container management

Increase of sustainability due to ecologically smarter transportation routes

Of course there are also some challenges with the Milkrun concept

Time consuming planning as quantity, duration, replenishment time, etc. needs to be considered

Processes and products need constant supply

Outbound Milkruns can be delayed by traffic or weather conditions

Economically relevant for larger business or higher demands of goods

Reliable supplier for products and transport needed

One last note for the internal Milkrun

Inbound the concept can be used in both ways, intralogistics and manufacturing. E.g. certain raw materials or semi-finished goods can be delivered on a regular basis to predefined workstations where the consumption can simply calculated. And on the fixed route the Mizusumashi can collect empty container and waste from production. This reduces internal ways of operators and guarantees a continuous supply of workstations. The next level would be to interlink all workstations or cells with your internal supply cycles to create an intralogistics flow, reducing the manual replenishment work. To find out what the Mizusumashi is just go here. In short: he/she is the guy who supllies goods on the shop floor in a structured process.

8D

8D Reports are used to communicate results of taken problem solving steps to the customer in a standard format.

The so called “8D”-Report is a document resulting from an 8D process which is part of a structured problem solving process in quality management if there are quality issues between customer and supplier.

8D represents the eight mandatory process steps that are performed when processing a claim to get to the root of the cause. The report details the nature of the claim, responsibilities, and actions taken to prevent the problem from reoccurring:

The 8D methodology is intended to ensure that complaints are dealt with systematically. Consistent documentation of the associated troubleshooting steps and a high level of fact orientation ensure that errors in the product or system are thoroughly investigated and thus permanently corrected instead of just solving the problem.

Application

These eight steps are performed for the 8D report:

1 Define a team to solve the problem

A team familiar with the process and/or the product is formed. They analyze the problem, take corrective actions, and monitor the effectiveness.

2 Describe the problem

In this step, the problem is defined as precisely as possible and the root cause of the problem is identified.

3 Containment action

These measures are intended to resolve the problem quickly and limit the damage until a permanent solution is found.

4 Root cause analysis

You probably haven’t found the real root cause during step 2 therefor various tests and experiments are used during step 4 to search for the real root cause of the error and the most likely causes are identified. This is intended to ensure that similar errors do not occur again.

5 Planning of counter measures

It then determines the means by which the causes of the problem can be eliminated. It is tested whether these measures solve the problem efficiently and no undesired side effects occur.

6 Check effectiveness of counter measures

Once the corrective actions have been carried out successfully, the immediate actions must be stopped. In the automotive industry, only process-improving measures are regarded as permissible shutdown measures.

7 Prevent recurrence of error

To ensure that such an error does not happen again, the team must initiate and monitor preventive measures. In the automotive and aerospace industries, manufacturers must use the FMEA method to assess the risks identified during root cause analysis. .Also, quality management system rules and procedures may need to be adjusted.

8 Appreciation of team performance and Lessons Learned

In a last step, the achievements of the team are recognized and experiences are exchanged.

Mentee

The mentee is the student of the mentor.

The mentee is the student of the mentor.

The term mentoring describes the development process in an organization where an experienced person (mentor) passes on his/her knowledge and skills on to a new/unexperienced person (mentee).

The overall aim of a mentoring program is to develop and promote the mentee’s personal and professional growth within or outside your organization.

As described the mentor refers to the role of a personal trainer whose experience supports the development of the mentee. There is also the cross-mentoring approach out there where experienced managers from different departments or companies and their high potentials (mentees) come together for tandems. Cross Mentoring usually is an externally organized program in which the tandems are formed in cross-functional and cross-industry teams.

Minimarket Principle

The minimarket is the smallest version of a supermarket on the shop floor.

The minimarket is the smallest version of a supermarket. The minimarket is typically a small area where operators can take parts from located on the shop floor. Typically C-Parts which are refilled following the Kanban/2-Bin principle. The minimarket is filled by the milkrun which pulls material from the supermarket.

Shop Floor Management

Shop Floor Management supports the consistent development of on-site processes and procedures.

Shop Floor Management (SFM) helps the constant improvement of processes and procedures on the shop floor. The presence of mgmt. level staffing in manufacturing and their recognition on deviations from requirements dramatically hastens decision-making and consequences with inside the on the spot implementation of solutions.

Shop Floor Management really defines control duties and calls for unique modes of conduct. Management is supported via way of means of the utility of unique equipment. Five Shop Floor Management-associated duties are performed on the Shop Floor and are as follows:

Install regular communication

Confirm processes

Empower/Qualify staff

Make it part of the continuous improvement process (CIP)

Conduct problem solving in a structured approach

SFM emphasizes behavior that encourages your staff to resolve issues inside their scope of capabilities and strive for continuous improvement.

For example, management maintains its remarks to a minimum, handiest makes binding commitments, offers however additionally accepts feedback, profits its personal attitude of a situation, lets in errors in mastering situations, does now no longer lay blame and places in vicinity wondering techniques. SFM tools help the effectiveness of SFMgmt. e.g.:

Production diary, KPI charts, hassle-fixing sheet, T-cards

Shopfloor Management

What is Shopfloor Management?

Shopfloor Management

Basic components of shop floor mgmt

Clear management roles and responsibilities

Regular communication (Gemba Walks)

Key Performance Indicators

Problem-solving techniques

Visualization

Some explanation of the basics of operational leadership in shop floor mgmt. you organization will for sure profit from clear leadership roles and tasks. Your employees want near help for independent problem solving. Large control gaps, wherein the direct touch among the supervisor and his personnel and associates is reduced, normally do now no longer show themselves.

The Japanese version of a classical institution leader (Hancho), with a totally small management margin and occasional willpower of the personnel, regularly does now no longer suit into the qualified operator in organizations. The excessive qualification of operators is a vital aggressive thing in industry. In order to make suitable use of those capabilities with inside the processes, disciplinary management has the mission of the use of SMART´en to acquire desires at the same time as keeping room for manoeuvre and keeping a very good stability among needs and help.

Managers at the first mgmt. level do now no longer meet those demanding situations via time control seminars, however via greater practical duties and requirement profiles. Examine whether or not it's far important to introduce extra technical management as an alleviation for the first mgmt. level to your organization (CIP coordinator, Kaizen Manager, Process Champion). This feature can stand up from the present functions.

Jointly have a look at the opportunities of dispensing distinctive information regions (5S, set-up time reduction, CIP etc.) with inside the assembly teams expand collectively with you a brand new blending answer specially appropriate for you.

Regular communication

Regular communication is the structured approach to create a framework on a regular basis for opportunities. In this rhythm issues can be carried out and discussed across the management levels. Regular communication is an integral part of the day to day work of all players in your organization.

This way of communication, no matter if you call it huddles, stand up meetings, shop floor meetings, etc. guarantees a continuous flow of information without loss of information itself as it is fast and recurring. A subject matter-associated exchange takes place where employees are enabled to independently define measures, hassle answers and pointers for development and to remedy conflicts as quick as possible.

The continuous flow of information between the departments throughout the complete organization is guaranteed through these regular and short meetings. One positive side effect is that with regular communication you will also calm down daily operations management by clearly separating the topics (e.g. operative commercial enterprise, 5S, CIP, etc.). It is vital that these regular meetings are performed continuously and adhered to in order that normal communique will become independent.

Key Performance Indicators

Regular communication can only exist if the information inside these meetings are defined and standardized. The standard of these meetings is not only the agenda but more important the Key Performance Indicators (KPI). The target of working with KPIs is to have a framework for employees that provides information on the achievement of objectives. When you want to successfully control your production be aware that KPIs are broken down in such a way that they have a direct connection to the operators or designated workstation. Only then they are becoming a real instrument of control by which teams and departments can be measured. The positive thing about KPIs is that with the continuous improvement process paired with a structured problem solving approach all employees will see the effect of implemented measures on the KPIs. To get the full information on KPIs go here.

Problem Solving

Problem solving isn’t always as simple as it sounds, but it clearly shows the effectiveness of clear shop floor management. There are plenty of problem solving methods out there (Ishikawa, 5 Why, A3, Root Cause Analysis, just to name a few) and lean methods (e.g. 5S, set-up time reduction, Hejunka etc.) are well known in the manufacturing industry. But these methods are there to help your organization to deal with more complex issues, this means that they are not really useful for operators that are dealing with daily production but more for a problem solving team consisting of employees from different departments.

To tackle problem solving the right and sustainable way the role of a Kaizen Manager should be installed in your organization in order to steer the problem solving and continuous improvement process. Kaizen Manager help you to get out of this “fire fighting mode” with a sustainable CIP culture.

Visualization

For a clear visualization of running process in your organization, cleanliness and orderliness is the main part of it. Clarity of your processes on the shop floor is the foundation for all lean manufacturing activities. Having the clarity the implementation and maintaining of visual management methods will guide you to a real state of flow.

There are different ways for visualization out there (find a deeper insight here)

The target with visual management and those methods are all the same:

Create transparency

Visual representation of procedures processes and services

Making problems (or bottlenecks) visible

All documents and information are daily updated and right at the place of action clearly visualized for everybody in the organization (e.g. blackboards, Workflow Boards, Shop Floor Boards, Andon Boards, etc.).

Following the PDCA cycle the status of problem solving activities are recorded and visualized. KPIs on different topics are installed and tracked and so on. Important is only that all this information follows also a clear structure and has its own spot on the shop floor (e.g. a shop floor corner). Visualization starts at the workplace of a operator and ends at the management board of the plant manager or owner of the organization.

But in the end it always supports the Continuous Improvement Process in order to bring your organization the next level or simply to overachieve your customers expectations. To get a full insight in Visual Management, read the full article here.

Sensei

In the lean world a sensei is a lean production expert that transfers his knowledge as mentor on to his mentees.

In the lean world a sensei is a lean production expert that transfers his knowledge as mentor on to his mentees.

To be successful with a Sensei it's been revealed that you need to start at the top and find a sensei to work with in order to engage all employees on the shop floor. As Lean activities reach industrial maturity, the role of the Sensei remains a gray area.

It is obvious that your organization needs a Sensei to adapt and successfully implement Lean principles. Therefore, the Sensei position will be your bottleneck in Lean implementation. In every Lean transformation process, one learns at some point that the success of a company consists in learning to learn.

As a little guide, consider the following three effects:

Learning curve: The learning curve of each department and initiative is tracked by their manager in the organization rather than having to compare it to established best practices across your organization.

Spillover: Effective learning practices are passed through hands-on, experiential learning from person to person within your organization rather than through predetermined processes.

Value-Based: Lean as a whole provides a learning framework that aims to balance customer satisfaction (which leads to organizational success) with employee satisfaction (and personal fulfillment) through a set of principles and tools aimed at discovering how MUDA can be reduced and value can be increased . Adding activities in all areas of the organization.

This approach has both sides of the medal, but the weak and the strength are lying in the learning path of each employee. Following the lean principles, every employee is expected to discover:

What do I need to learn: What is my personal challenge in order to better align my work with customer value and thus sustainable and profitable growth with the satisfaction of all my colleagues to reconcile.

Learning from the shop floor: The learning style is deeply embedded in daily operations. Employees are learning results from their support of learning activities at all levels. Because all employees solve their problems or show initiative, everyone is expected to interpret the conclusions of others and find a way to adopt the solutions to their own work. It is the responsibility of the Sensei to support its learners in this learning phase. Learning by doing is the correct way to describe it.

Create a learning environment for your employees: Learning on the job is never easy, especially in today's business climate. Consequently, one of the key functions of a Sensei in the Lean perspective is to create a visual environment for employees where it is easier to recognize than normal and where opportunities for continuous improvement in small steps (Kaizen in Lean jargon) are clearly visible Everyone. A learning environment also means a stable affective environment where mistakes are not punished but seen as a source of learning.

The Sensei is not a boss at all. He or She has no power and can only suggest. The Sensei's task is to help all employees in your organization to develop their own lean thinking through practical exercises in workshops. The Sensei's job is to convince middle managers that solving today's problems will, in the long run, prevent tomorrow's fires.

The essence of Lean is learning while solving problems. This is a difficult task at the best of times, and indeed every person in your organization must be taught to learn how to learn. In relation to managers, the Sensei has five main roles of support:

Finding problems

Tackling problems

Creating problems

Solving problems

And finally learnings from problems

"If you have no problems, you are dead". is a classic lean principle. Perhaps the most important part of Lean's problem-solving learning approach is the initial problem-finding phase. Lean's approach to business is to capitalize on every problem.

“Sometimes you WIN sometimes you LEARN!”

5M Method

5M Method is an other way of describing an ISHIKAWA Diagram.

5M Method is just an other way of describing an ISHIKAWA Diagram. This diagram is pre-structured with five given categories of potential causes: “Man”, “Machine”, “Material”, “Mileu = Environment” and “Methodology”. In a more detailed form of the environment you can further divide it in “management” and “measurement” which then is considered as 7M methodology.

One Piece Flow

One-piece-flow is a principle to cut production lead times.

The term One-Piece-Flow basically describes the radical reduction of lead times through flow-optimized production. In an ideal state processed parts or components are moved from one process step to the next without any interim storage. The quantity moved consists only of one part or one batch. You will only be able to achieve this when your work systems are closely connected. The transition of a work system to an one-piece-flow oriented system can only succeed if there is a high availability of existing capacities and flexibility.

Getting your production to flow combines increased productivity and increased employee motivation.

As with most of the lean terms the one-piece-flow principle made its way from the Toyota Production System where it is referred as operator centric work flow. Instead of day in and day out performing the same task at a fixed work station the operator moves with the workpiece through the complete process steps, station after station, for which he/she has to be qualified for all process steps. It is quite similar to a Chaku Chaku line, while Chaku Chaku describes a concrete line layout, one-piece-flow is a principle or mindset so to say. The basic idea behind it is to reduce defects through lacks of concentration and increase motivation of operators through variety.

Lean Manufacturing terms might seem complex, but as most of the time, the principle behind is straight forward and quite simple. As they seem to be no brainers they easily get forget about it which will automatically lead to waste. The best example for waste is the so called TIMWOOD(S), where two main drivers are high amount of Work in Progress (WIP) and high inventories.

Now let us have a look how the One-Piece-Flow principle can help.

The principle of One-Piece-Flow is a new form of flow production. In contrast to conventional forms of flow production the worker in the one-piece.flow production does not remain in his place. Generally speaking the operator has no place of his own - he is always moving with the good. This is exactly where the reference to Chaku-Chaku comes from. With the sequence principle, on the other hand, the operator only interacts with the workpiece on one process step.

After on part is finished the operator starts again at the beginning of the line. This procedure comes with certain demands on the assembly line. U-Shape Layout is the most favorite one, as start and end should be as close as possible to each other in order to keep ways short and transition seamless. The U-Shape Layout is also great as raw material and other components are supplied from the outside, what makes the job of the Mizusumashi easier, and the value adding activities are on the inside.

But speaking about the advantages of One-Piece-Flow, the try to make it short:

Arrangement of workstations simplifies the arrangement of operators

If deviations occur, the operator knows exactly where it is coming from

With the CIP the continuous optimization is really driven on a constant basis

Applied correctly, lead times are drastically reduced

Inventory is drastically reduced

Used space on the shop floor can be reduced by 60% compared to conventional production

Motivation of operators raises as they are responsible from start to end and do not have this monotone daily routine of just one work station

In addition, the use of U-Shaped assembly lines, and if they are build up on standard profiles or standard shelvings, it gives you a huge amount of flexibility. Where workstations or the complete line can be easily extended, reduced or adjusted to new needs.

Stay Connected

Ad

We want information fast and in a nutshell. We from OI recommend Blinkist* - because it’s simply the best.

* = Affiliate Link