GENERAL MANAGEMENT

Process Map

The Process Map is a visual representation of a sequential process flow. Typically used to visualize a process in the beginning of a Kaizen session but also applied as a tool for problem solving.

The Process Map is a visual representation of a sequential process flow. Typically used to visualize a process in the beginning of a Kaizen session but also applied as a tool for problem solving.

Having a Step-by-Step Guide on process mapping can be beneficial, this is the reason for the following section where we try to give you some guidance.

Process Mapping describes nothing less than creating a workflow diagram with the target of getting a clear understanding of how a process itself and its sub- or pre-processes work.

Mapping

By mapping business processes you have a great way to understand all process steps along the workflow. With process maps, specially your upper-level mgmt. can easily understand how processes are functioning and what it takes to run through the complete workflow.

Of course the main question is what to use Process Maps for?

In general process mapping is carried out to establish organization wide standards or procedures. There are examples out there in the industry that use process maps as standard work instructions. The downside by doing so is that you will miss a lot of KPIs by this approach - and we all know, if you can not measure you can not control. This is the reason why process mapping usually is done in the beginning of setting up a new workflow, it supports the management by visualizing of what and how it should happen.

You might have come across Business Process Management (BPM) software. Generally speaking it is just software the helps you to track the lead time to complete a process and to identify bottlenecks. By this you then have the chance to implement standards that tackle automation of work.

So let us have a look step by step. In the following we will show you the general steps of mapping out business processes.

1 Set the scope

Be specific where your process starts and where does it ends. It might be absolutely reasonable that some process have more than one possible end, therefore it is crucial to map down all possible outcomes.

2 Write down all activities that are driving the process

As you already know where everything starts and ends it’s time to fill the gap in between. It is up to you how detailed you want to describe it. Just make sure that is is formulated as an action item.

3 Get the actions in order

Great work, you determined all action items that are necessary to run your process from start to end. Now it is time to set them in order. Each action has to trigger a downstream process step, otherwise you have to question the action item itself, do you really need it if there is nothing happening afterwards.

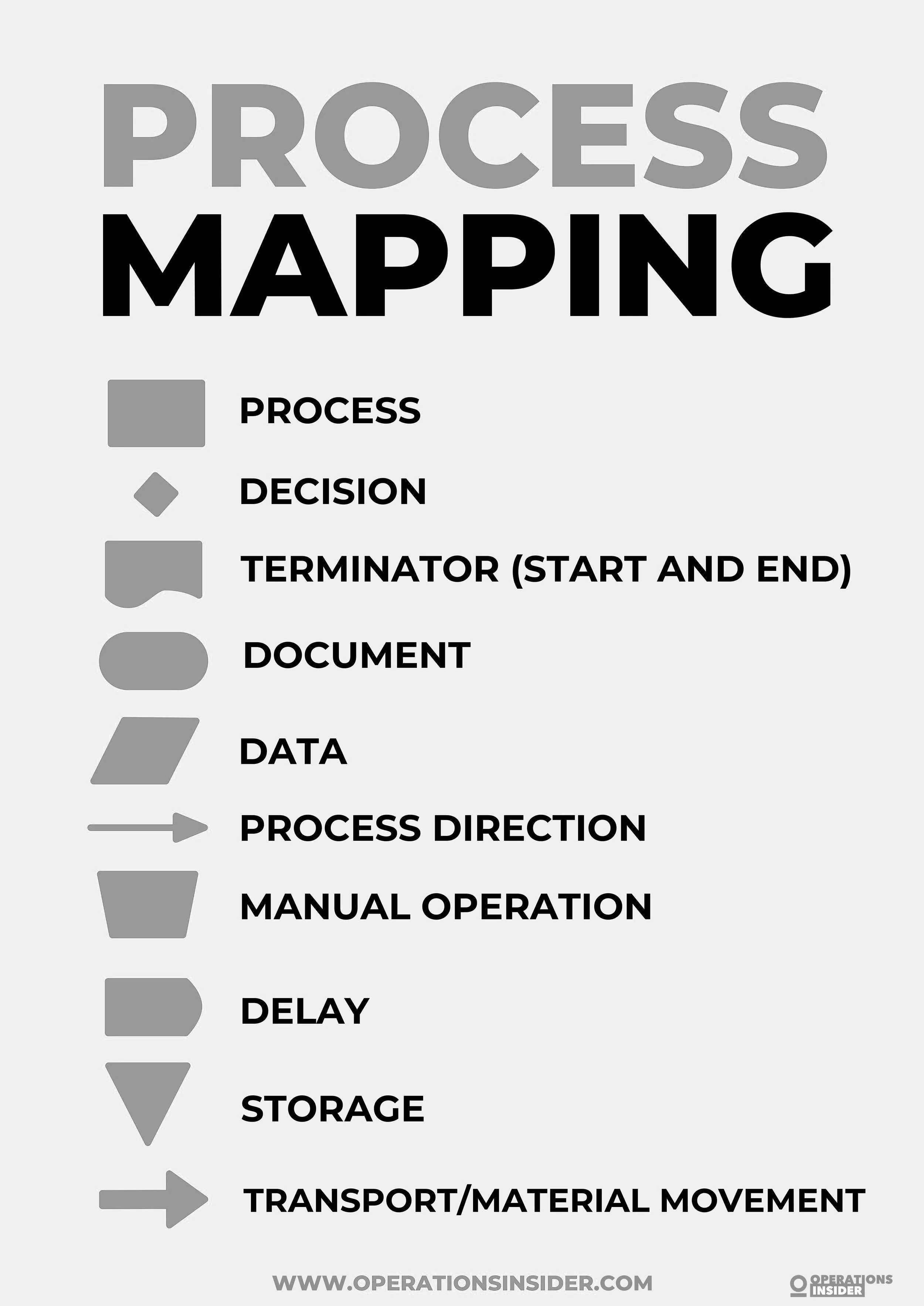

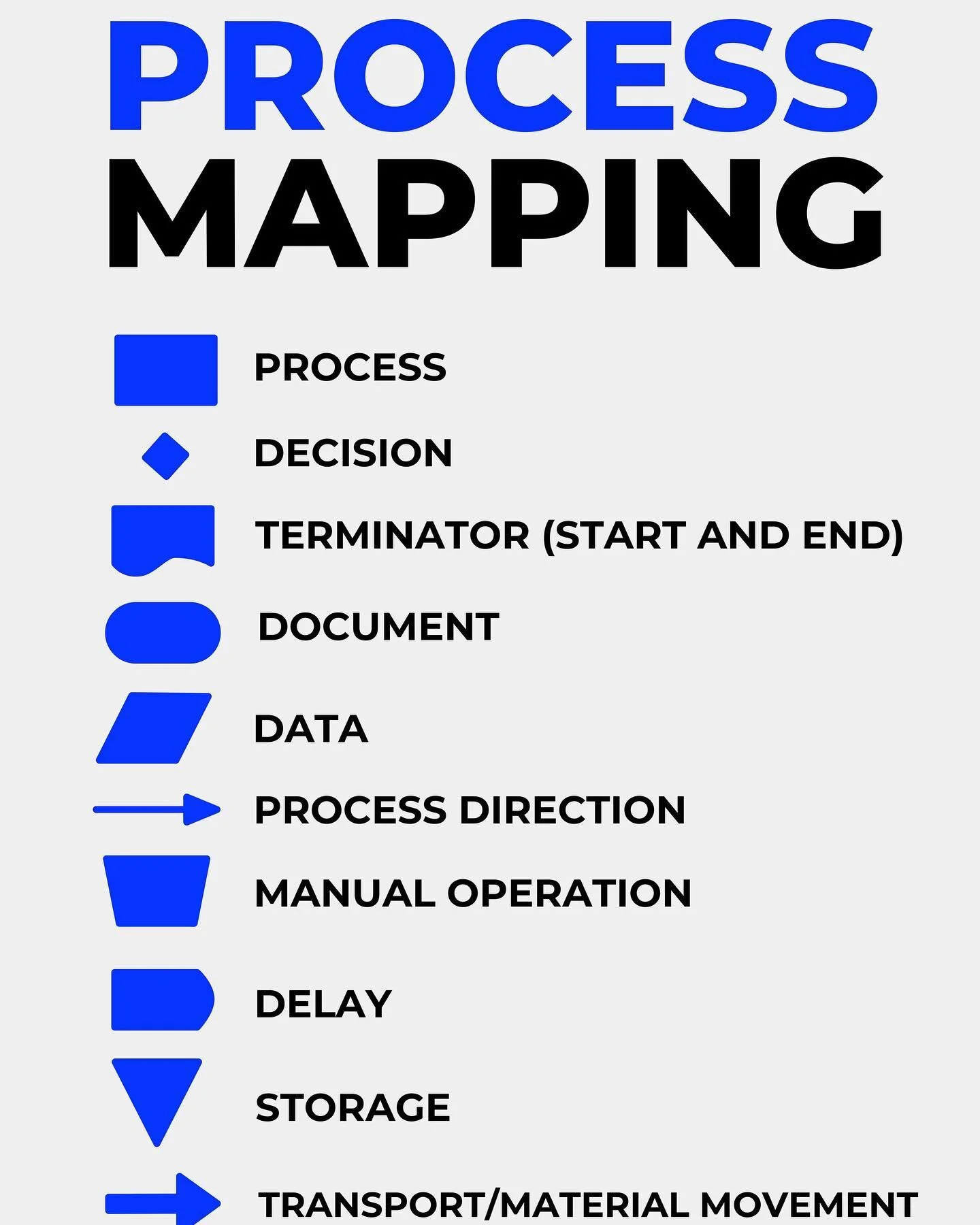

4 Use Symbols

Just make sure that you are using correct symbols to map your process steps:

If the process you’re mapping is a closed loop, make sure that it takes you back to the beginning.

5 Systems Modeling

Use the systems modeling approach to draw your flowchart and map your processes. It helps you determine what information should be added and where.

6 Double Check

Once you’re finished, let it rest for a day, step back and make sure that the process you have drawn is complete and that it contains all relevant information. Add the date and an appropriate title so you can keep track with upcoming versions of it.

7 Review and Improve

Once your process is mapped, have a look (GEMBA) and see if the process is running as it should run in real life. Are the people involved following the ideal state of workflow? Are there any unnecessary steps that can be crossed out? Making continuous improvements is key to run efficient and target-oriented processes.

If you want to see process mapping in a high level approach, go have a look at quality professionals working according to the Six Sigma principles. Following the business process architecture, it sees all processes as a series of cross-functional flowcharts with a different level of complexity, reaching from 0 as almost none details up to 4 being very detailed.

Having the lean manufacturing glasses on Value Stream Mapping (VSM) takes best practices and is used to improve the flow of materials and information that are required to deliver a product or service to a customer, that is willing to pay for. VSM is an end-to-end approach and has its strengths when it comes down to cut lead times or simply implement lean manufacturing principles.

No matter what - when you start mapping your process, think about upfront what the target state of the map should be. By this we also mean the format, that it suit the next steps, such as usage in different software.

All together it is always a good advice and fast help to write down your process steps on sticky notes and arrange them in the right order on your office wall - you might also use the affinity diagram upfront, to place everything in their natural order.

This is the good old-fashioned approach you don’t need anything for, just a pen and sticky notes.

Policy Development

A one-year plan, reflecting the long-term vision and the 3-5 year strategic planning objectives. In this case shown with the Hoshin Kanri approach.

Policy development can be seen as a one year plan that is reflecting the long term vision and 3 to 5 year planing objectives. It is following an implementation process that focuses on a few major, long term customer focused breakthrough objectives which are critical to the long term success of your company. This development process links your major objectives with a specific plan to support your organization on this journey.

In the lean world while talking about policy development the term Hoshin Kanri comes real quick on the table. Therefore we want to talk about Hoshin Kanri and how to develop strategies and how to derive your objectives.

HOSHIN KANRI is an organization-wide planning and control system. Too often new strategies fail in the implementation phase or simply don’t have the expected effect. This can have several reasons:

Missing internal support on employees and executives for the strategy itself

It is not clear stated on which goals each employee should focus

Missing competence on employees and executives to implement a strategy and how to execute in daily operation

Splitting up the strategy between departments leads to separated solutions that probably do not support each other

There are several weaknesses in the planing and implementation that should be avoided on first hand when using the Hoshin Kanri approach. Coming from the lean driven operations side some principles should be adopted:

Management level is clearly involved in the process of strategy development and responsible in the implementation phase - they have to be role models and function as coaches

The breakthrough objectives define targets that the whole organization focuses on - including side-effects between the departments themself

Employees and executives are given the freedom and competence to increase their own performance

A cross-functional steering committee is installed to observe the progress on action plans and their fulfillment towards the common target

Time to develop the organization-wide strategies

The long term mission with a Hoshin Kanri Management System is to prepare your organization for the marathon not the sprint. In order to achieve the long term success it is a necessity to build up competencies in leadership and to build up a corporate culture and structure that can deal with it.

With the Hoshin Kanri approach one great part of lean manufacturing and management comes across our way again. The PDCA cycle. The Process of Hoshin Kanri is therefore following the 4 Steps of the PDCA:

PLAN

Agreeing on goals and measures

DO

Empowering managers and employees

CHECK

Track and show the development through visual management

ACT

Live Hoshin Kanri and make it a fix part your management system

Hoshin Kanri was one of the first management systems that already took the mid-managers in responsibility to define the companies vision and does not leave it for the C-Level Managers only. It is the same with defining breakthrough targets derived from the vision and strategy. It is crucial that the mid management defines as well which path they are going for the next 3 to 5 years.They have to show their performance to the top management over the upcoming years and report the planned improvements in the steering meetings.

Based on the vision, strategy and defined breakthrough targets, the next level of Hoshin Kanri is to define the mile stones which have to be met in order to reach those breakthrough targets.

Now get this out in your organization

First of all - to be clear you will not achieve anything when you have different departments working on different topics. Make those planed measures to cross-functional tasks. This ensures that everybody is working on the same page.

Like with the management method - “Management by Objectives” - also with Hoshin Kanri you cascade down the targets to the next level. The main difference is that with Hoshin after the target definition and the developing of an action plan their must be a cross-functional coordination between the departments, groups and teams incl. the C-level and mid mgt. This gives your organization the chance to see those effects and interdependencies between all players of your organization. This process is the so called catch ball - it gives the participants the possibility to “throw” around ideas before agreeing on common targets. If you are a superdooper organization you are doing this with all employees. And in the end everybody gains a better understanding of how they can support each other to achieve the overall organizations target.

Next step for a successful transformation - develop leadership skills

Most of the companies out there are super busy in planning the next big thing, strategies and great visions, but in most of the time it seams like nothing is happening. Don’t get me killed but coaching is a necessity. Just google the story of “Sharpen the Saw” (The 7 habits - by Stephen Covey). The reason behind it is a lack of skills, e.g. if your employees don’t even know what a PDCA cycle is, don’t expect them to achieve your vision. Furthermore if the objectives are not integrated into the daily work and management routine, all tasks are seen as an extra burden nobody wants to have.

Hoshin Kanri pays special attention by developing leadership skills in the organization that are needed to make a real significant change. Based on the Lean Leadership Model it is build up in four levels of development as leader:

1. Develop yourself as a leader

When you see yourself in the future, with a living Hoshin Kanri Mgt. System, you have to walk the talk. That means you have to develop competencies to reflect your behavior and effectiveness in order to increase your own performance. This is also known as train the trainer.

2. Train and developing other people

The second level can be seen as the trainer, you are not the manager you are the coach that develops the competencies of his team to be able to reflect on their own on their actions and reactions. You initiate their own learning curve.

3. KAIZEN (Continuous Improvement Process)

Best way, in my opinion, is to install regular huddles. Short, max. 15 minutes once per week in the morning, to see the progress. Is everybody going in the right direction, does the CIP action meet the direction of the overall target, etc.

4. Create a vision and get target agreements

At the last level, all management levels should be involved. This is the time when you want to get rid of the departmental views and align all activities towards the organization wide overall agreed targets.

Now - how can you support your employees ?

With the Hoshin Kanri System you are giving your employees the right tools in order to achieve the defined breakthrough targets in addition to their day-to-day business. A well known tool is basically a simple piece of paper, the A3 report. Read more about the A3 here (great book for A3 systematic approach).

The best-known A3 report is the problem-solving report. In this case, the responsible quality representative takes the standards through a systematic process that makes it possible to describe the symptoms that have emerged. It is assumed that the cause is not known, but that the effect is evident. Also the A3 is following the PDCA methodology. But before we go into details, if you want to read more about A3 itself go here.

Specially when you go in the Check Phase, Shop Floor Mgt. plays a crucial role of the Hoshin Kanri Systematic. Managers shouldn’t get stuck in the paper work, but do those Gemba Walks. In the lean world it is all about the value adding actions not the paper work. Managers should go and see at the place of action and focus on the deviations of how it should run in order to speed up the performance. With this approach you will also improve your employees’ improvement capabilities which brings the problem solving capability to the lowest organizational level possible.

Following the Shop Floor Mgt. Systematic - You will make the development transparent

This means that the visualization is a central part - not only as an element of the shop floor mgt. All defined KPIs and developments of focus topics are displayed graphically at the place of action. E.g. the production fulfillment of a manufacturing line is displayed at the line on the cell board. Following the information and meeting cascade, all information is funneled bottom up and thereby distilled to the core information.

The idea behind all this is to have a stable routine and processes to reduce the impact of coincidences or unplanned interruptions. This means also the implementation of standard work incl. the CIP of processes themself. Your complete organization is trained to constant change in order to continuously raise current standards and challenging the status quo. Main impact therefore has the problem solving skills - description, root cause analysis, defining measurements, fast decision making, then the rest of the PDCA > DCA. All this is triggered by deviations seen in the visual management. You see speed is everything.

How to steer the development process

In order to steer the development the required communication cascade has to take place in a daily routine. Those needed shop floor meetings are necessary so employees are constantly focusing on the Hoshin targets by challenging the performance on a daily basis. Following the meeting cascade also the plant or group manager are involved daily to meet up and monitor the level of achievement and can react fast when deviations occur.

One top level methodology is the so called “Presidents Diagnosis”. This means nothing less than that the top management personally visits the manufacturing sites and audit their performance. This diagnosis is based on eleven criteria:

Management

Financial Mgt.

Human Resources Mgt.

Supply Chain Mgt.

IT

Quality Mgt.

Sales and Marketing

Engineering

Manufacturing

Maintenance

Material and Logistics

Each category is rated based on its current status according the PDCA cycle. With the Presidents Diagnosis there is even a fifth phase added the so called “Scan Phase” which leads to a three step model of the diagnosis itself:

Self-diagnosis of teams and departments

“Presidents Diagnosis” by top level management

Recognition of target achievement by top level management

Following the PDCA methodology you will now secure the achieved with the help of standardization

One big point in Hoshin Kanri is to secure what you have achieved by standardizing it. Follow up activities in the act phase are there to keep the achieved and have a new starting point to improve it further. Standardization therefore is the first step of manifesting Hoshin Kanri in your organization.

To be clear with standardization we mean the standardization of processes or activities customers are willing to pay for. In best case repetitive processes not depending on persons, time and location. With Hoshin Kanri you will differentiate between simple and complex processes. In addition also the management of Hoshin Kanri will experience the standardization process.

After the first round of standardization, KAIZEN takes the stage. Kaizen means nothing less than a step by step approach of continuous improvement. Combined with Hoshin Kanri it means the continuous improvement of standard work.

Last but not least time to review the development of the management

In the end with all lean activities, it all comes down to leadership development. That is why also the Hoshin Kanri Systematic continuously checks on the developed of competencies of its managers. Based on the Lean Leadership Model following questions are evaluated:

How have managers developed themselves?

How well have they developed others?

Do they conduct kaizen activities daily?

Do they lead their teams in the direction of the overall target?

Hoshin Kanri is depending on the Lean Leadership Development Model. This ensures the further development of people from the shop floor to c-level and drives the development of a lean culture and continuous improvement.

Stay connected

Ad

We want information fast and in a nutshell. We from OI recommend Blinkist* - because it’s simply the best.

* = Affiliate Link