LANGUAGE OF LEAN

Blue Ocean Strategy

Blue Ocean Strategy: Innovation to develop new markets.

Innovation for New Markets

The blue ocean strategy leads out of the shark tank: instead of copying the competition, companies find new markets.

Blue Ocean strategy: Off to new markets

Which company does not dream of an untouched market? And how many companies are stuck in the constant, sometimes ruinous competition and are treading on the spot? In order to escape this fierce struggle for survival, a rethink is necessary: If your own market or the market you are aiming for is too fiercely contested, you create a new one.

Opening up new markets is the core idea behind the so called Blue Ocean Strategy. To explain it simple the Red Ocean stands for existing markets where the sea is full of blood and therefore red, the Blue Ocean is the untouched, sweet spot of sea where nobody was before you.

I think we don’t have to discuss the obvious advantages of an untouched market. At least in the beginning you won’t have any competition. Your organization can act instead of react which automatically gives you higher turnovers and returns. But it is for sure not risk free, failure can get you everywhere. And even worse you will swim all by yourself not finding any customer and starve to death or die of thirst.

Customer Centric Focus

The Blue Ocean Strategy comes with several tools with which your organization can create new business cases. What they all have in common, is the focus on the customer benefit, regardless on the how to sail the blue ocean. Just think about technological innovation.. typically driven by making the customer lives more comfy.

Analyze and reposition your offer

The Blue Ocean Strategy first starts by analyzing your existing offer, which has to be done from the customer perspective. This is followed by the competitors analysis, what do they have that customers buy their products instead of ours, what is the extra value? The outcome is then recorded in a so called value curve.

The next step is the usage of the so called ERIC square. A typical tool to redesign service offers of drive product developments. The Blue Ocean gets a shape.

The E stands for Eliminate: What existing features are obsolete for the new use case?

The R means Reduction: What is important for the customer but can be reduced to an absolute minimum without being kicked out?

I for increase: What product features should be raised above the existing standard?

And finally C for Creativity: What awesome features does the customers want but don’t know yet?

A slightly different approach can also be the use of the Osborn Checklist, but won’t be covered in this article.

Creating Blue Oceans

Let’s face it, you can have the best product in the world, but without a market it is worthless. This already indicates the crucial factor of success of a blue ocean strategy, e.g. creating new markets or at least expand the existing one. To help you getting to new markets six paths can be taken:

Are there existing strategic groups in the industry?

Are alternative fields of operation possible - and if so, which ones?

Is there a potential target group that has been ignored so far?

What are the new mega trends that others haven’t recognized yet?

Are there complementary services or goods that nobody has on the radar?

What functional or emotional motives would customers want to buy the new product from?

Following these questions already shows you that the Blue Ocean Strategy rarely ends up in a completely new and disruptive product. The reality is that different product features are combined and given out to the market as new release. That is for sure not the idea behind the Blue Ocean Strategy, but used for it. The benefit of the Blue Ocean Strategy is to turn non-customers into customers. These folks are your blue ocean.

Have a look on Show Stoppers

Like with all theories, the Blue Ocean Strategy seams quite simple. But no matter what and how you do it, make sure to have a clear and transparent communication throughout your organization. Everybody has to be on board and support the planned journey, otherwise chances of getting stuck at the harbor and not setting sail are quite high.

And finally, when set goals or targets think about SMART, most important > it has to be realistic - can’t say this often enough.

Checklist: Blue Ocean Strategy

In summary, the following aspects must be taken into account in the Blue Ocean Strategy:

A saturated market with predatory competition does not permit growth.

A new, unrivaled market is created through beneficial innovation.

The existing offer is analyzed from the customer's point of view.

A new range of services or features is created.

Employees in the own company are involved in the implementation.

SMART - OBJECTIVES

SMART - Objectives drive us forward and continually remind us of what we want to achieve. They help us to set priorities more clearly, to focus better and give us the strength to continue, even if our motivation is low.

Goals are helpful both in our daily work and in our personal lives, as they give us something to work for.

SMART - Objectives drive us forward and continually remind us of what we want to achieve. They help us to set priorities more clearly, to focus better and give us the strength to continue.

HOW TO DEFINE GOALS

Objectives can be manifold, but one of the best known methods to describe goals is the S.M.A.R.T. methodology. The 5 steps can be used to clearly describe a goal and make it "tangible".

The acronym SMART stands for the following 5 steps:

S - specific | Clearly defined goals

M - measurable | The target should be measurable (has a KPI)

A - accepted | The accessibility of the goal should be accepted by all stakeholders (alternative: ambitious/attractive)

R - realistic | The attainability of the goal within the set framework should be realistic,

T - terminated | The time of target achievement is clearly defined.

FURTHER DEVELOPMENT, SMART BECOMES SMARTER

Some of the terms have changed over time. So the A at the beginning stood for agreed upon. This is from the thinking that the term is used within a company. In this respect, it was important that a goal was accepted by all involved. Over time "agreed upon" often became "achievable" or "attainable".

Not only the terms themselves have changed. The acronym itself has often changed recently. Many authors have switched to making SMART - SMARTER.

The E stands for "evaluated".

The R stands for "reviewed."

More than 200 pages about OKR may seem like a stretch – and there is a bit of extraneous material – but those who must lead an OKR initiative, especially novices, will value this substantive guidance.

Read the pick here.

In my opinion, the popularity of SMART goals stems from the simplicity of the method and the higher probability of success. Why should it be higher? Now the SMART method requires from the person or department that set the goals a certain time and focus on those goals. When one is so intensively involved with defining goals, one inevitably thinks of ways in which the goal could be achieved. Furthermore, one has already taken the first step and is now more motivated to take the next necessary steps.

Of course these steps must not be missing. Action plans must be derived from the goals, whose degree of goal achievement should be regularly reviewed. Regular monitoring of progress enables me to adjust my next actions to the achievement of my goals.

PDCA

The idea behind the PDCA cycle is to empower employees to independently identify and solve problems. It is also a crucial element of the continuous improvement process (CIP).

The idea behind the PDCA cycle is to empower employees to independently identify and solve problems. It is also a crucial element of the continuous improvement process (CIP).

Many projects in which a culture of continuous improvement (CIP) is to be anchored also fail because of the tools required for this. With the A3 Report, for example, there are such tools. Just for clarity upfront, problem solutions, decision bases and strategies are presented on a sheet of paper in DIN A3 format. The A3 Report provides employees with a kind of template for which analysis and action steps must be taken when solving a problem. This process, in turn, is based on a systematic approach: the PDCA cycle.

The four phases of the PDCA cycle

Of all the quality improvement tools, the PDCA cycle is the most important. It describes the basics of an improvement process and divides it into four phases:

Phase 1: Plan

In this phase the problem and the actual state are described, the causes of the problem are analyzed and the target state is defined. In addition, measurements for reaching the target condition is defined.

Phase 2: Do (Implementation)

In the implementation phase, the predefined measures for achieving the target status are fixed.

Phase 3: Check

In the review phase, the experience gained and the results achieved in implementing the measures are reflected and the measures are readjusted if necessary.

Phase 4: Act

In this phase, the experience is gathered and the problem-solving process is evaluated and standards for future action are derived.

PDCA Cylce

Teams always go through this process when they have identified a problem or a relevant opportunity for an improvement. Then a new PDCA cycle is started with the aim of establishing a new standard in the company which serves as a basis for further improvements. The following case study shows how working with the PDCA cycle works.

The PDCA cycle explained using a case study

The management board of an electrical motor manufacturer has adopted a new strategy to further expand the company's quality leadership in electric motor production and increase customer satisfaction. To this end, the management team defined the following so-called breakthrough targets:

The production processes must be state of the art

The work must be based on the zero-defect principle

The striving for continuous improvement (CIP) should be anchored among the employees

These goals have been broken down to all levels. At a meeting, the head of department pointed out to the group leader that the five pressing lines he supervised produce less than the target of 35k motors per day. The consequences: Supply bottlenecks and customer dissatisfaction. The group leader should now solve this problem. In accordance with the PDCA cycle, the following procedure was followed.

This reading pick is from experienced manager and lecturer Ron Basu he lists tools and techniques you can implement to make the best use of Six Sigma and Lean Manufacturing, two major quality-control programs.

Read more here.

PDCA Phase: Plan

The group leader analyzed the production figures of the past weeks. He found that the joining line supervised by the team leader only delivers an average of 32k motors per day instead of 35k. The team leader suspected that this was due to high line rejects. They then took a look at the sorted motors in the quarantine stock. The result: the labelling on almost all rejected motors are displaced or not readable.

The group leader asks the team leader what could be the cause of the problem. His assumption: "The printer is not running perfectly and the application process is not stable. A check of the incoming labels has proven that all material is in specification, so the failure has to be within the printing and application process. The team leader then looked at the scrap figures in the shift reports. It turned out that over 80 percent of the rejected motors are produced during the night shift.

So the group leader and the team leader observed the labelling process in the following night shift. They noticed that the labeling belt occasionally jams in the conveyor belt, which is why the labels are applied offset to the desired location. The team leader suspected that this was due to the fact that the printer mounting and so the printer location was in the wrong position, a further analysis has shown that a new employee has been placed in the night shift and he didn’t understand the correct setting and placement of the printer after exchanging the labeling roll. In addition, it came out that the cartridge has to be replaced after 24 hrs which also was usually coming to the night shift. So the root cause was clear.

The group leader then asked the team leader to formulate a target state for possible countermeasures. He knows through trainings that targets should follow the SMART rule, but on this topic mainly measurable. He wanted to achieve the target by training the new operator. Done deal.

PDCA Phase 2: Do

But the group leader was not satisfied with that. He asked the team leader if he knew exactly how the operator were going to change roles and cartridges if there was a standard operation instruction (SOI) of this process and how to train new operators. The team leader denied this.

In the following night shift, they both watched the change of roles and cartridges by experienced and inexperienced operators. The experienced operators made sure that the labels did not touch the floor during the change and that the printer is in the correct position after replacing the role. The inexperienced, on the other hand, often rubbed the labels on the floor and just pushed the printer in the station without checking the first parts after replacement. Dirt gradually collected in the label dispenser, causing the tape to jam from time to time and the incorrect position of the printer led to misplaced and crushed up labels which in the end of line led to the rejects of the motors.

The group leader asked the team leader and his team to consider possible countermeasures, prioritize them and draw up an action plan. The countermeasures were among others:

5S sessions at the end of each shift to restore cleanliness and order in the line

Installation of training matrix in order to know how is able to follow the process and how is experienced enough to train new operators

Install a Poka Yoke fixture to ensure a process stable positioning of the printer

Install a counter with light indication when the cartridge of the printer needs to be replaced after an evaluated amount of labels printed

Based on the prioritization, the team members drew up an action plan. They also agreed:

The current status of the project is always documented on the cell board of the labelling line for the next three months

The progress figures are reported in the daily shop floor meeting – not the team meeting of the cell. It has mgt. focus.

PDCA Phase 3: Check

In the following weeks, the team leader of the cell reported daily the figures and the impact of the measures on the outcome. They also defined further measures on the basis of their experience to date. For example, the machine is always stopped when the label tape reaches into the light barrier, caused by an air blast. The measure was to install a duct for the carrier tape of the labels into a bin placed under the line, easily accessible for the line clean up at the end of the shift. As a result, the reject rate fell by almost 80 percent after three months. The initially formulated target of 40 percent fewer rejects was achieved.

PDCA Phase 4: Act

After this assessment, the group leader asked the team leader what he wanted to do with regard to standardization. He replied that he would prepare a written description of the optimal process "maintaining the label printer" as well as for training new operators. In addition, from now on he will carry out a daily process control in order to detect target/actual deviations earlier.

The group leader praised the team leader and asked him at the next team leader meeting to inform the team leaders of the four other production lines about the new standard and the findings in the PDCA problem-solving process so that they could learn from the experience. Him himself informed the head of the motor production department that the problem of insufficient motor production had been solved.

Doctor Nurse Principle

The operator creating the value (doctor) receives the materials and tools from the logistics provider (nurse), so that his/her primary activity is not interrupted by secondary activities.

In the Doctor Nurse principle, the operator creating value is considered as the doctor, he receives tools and goods he needs to do his job from the nurse in this case logistics. For this reason, the doctor can’t do his job without the support of the nurse.

What can we learn from hospitals and how can we adapt it to the lean world.

In hospitals it is crucial that the doctor can fully concentrate on a surgery, the doctor is the single point of contact towards the patient using his tools combined with his training. Everything distracting him from being focused has to be eliminated. In order to give him this capability he needs assistant right next to him. The nurse’s job is to support the doctor and provide him with all equipment, tools and material he needs just in time.

Applying this principle to production is not that hard. To use the doctor nurse principle on the shop floor some requirements have to be met. As mentioned think about the operators as the doctor, they have to concentrate on production. As they are the once generating value for the whole organization by assembling the components which customer are willing to pay for – they need to be placed in the center of all activities – the rest is supportive.

In lean manufacturing this is called the line-back approach. Primary processes are the once that add value so focus on the operation and prepare everything that supports it. The nurse takes care of all other activities, most of the time non-value adding activities but necessary.

Doctor Nurse Principle

Arrange the work station in a way that gives the nurse free accessibility to the work area without disturbing the doctor, i.e. filling up kanban shelfs with new material while simultaneously removing empty boxes.

With the approach of separation of primary and secondary processes in two physical areas none of the process will be interrupted by the other.

In addition, this principle is driving the mindset of the organization to focus on a lean production process and how best it can be supported. If you do so, you will also have the advantage by separating value-adding and non-value-adding activities to find you approaches to minimize the non-value adding activities.

Another way of calling the nurse a nurse is a water spider or in lean terms a Mizusumashi – the inbound material supplier.

Shojinka

Constantly improving the amount of workers in a production cell to match the volume of demand and type which has been given to the unit - requires that training is provided to every worker in various process steps.

Constantly improving the amount of workers in a production cell to match the volume of demand and type which has been given to the unit requires that training is provided to every worker in various process steps. The layout of the work cell is done in a circular or U-shaped layout, where the number of operators performing can vary and be adjusted. The capacity and ability to have an adjustable manufacturing process is relevant to meet the demand profile and have a sustainable growth.

Ever thought if there was a particular way through which you can use less manpower but produce more? Needless to say, there is a way through which you can do this: Maximizing the output while simultaneously minimizing the input is a business 101 idea and theory that we carry with us since inception, and strive hard to completely tackle for the whole of our careers.

There certainly is a way through where you can do more with less, and that way is known as Shojinka. It is also referred to as "flexible staffing" or "flexible manufacturing." Shojinka is again a Japanese term, and it was born from the lean manufacturing principles of Toyota. There is no denying that the idea of "flexible staffing" has proven to be the best performer in lean theory.

So what can be understood as Shojinka

Primarily, Shojinka is defined by two elements. The first one is the operators are trained on several workstations and following a qualification matrix. The second one is the layout for the work cell, of cause preferable in a U-Shape layout rather than a straight old fashioned line, but this has to be discussed in all cases separately.

Let’S have a look on the Pros and Cons of Shojinka

Pros

Flexible staffing, as its name suggests, has the biggest advantage in that the staff is flexible. This means that the operators have been provided with training in almost every part of the production following the qualification matrix.

This will enable them to work in areas of production where there is more demand or will allow them to switch quickly as the demand changes. Unlike a highly specialized working environment or fixed linear manufacturing, flexible staffing allows you to keep your efficiency high under every type of manufacturing demand, rather than an ideal pre-determined set. In addition to this, Shojinka also provides an opportunity for operators to work on improving products or on the various side whenever the demand falls all across the board. It will not only enable your staff or the operators to become more effective and efficient at changing levels of demand, but it will also allow them to swap between these specific levels on a shop floor that has been properly and correctly set up.

The inputs and the final outcomes are kept on the identical and corresponding sides of the work cell due to the U-shaped manufacturing line, which ultimately helps your organization of logistics and transportation. Furthermore, it also enables the operators to move conveniently between the first process step and the final process step on an assembly line without the need to walk its whole or complete length.

Cons

As soon as it has been implemented and applied, there are almost no cons to the Shojinka assembly line.

But to start off implementing flexible staffing you need to clear of some major obstacles to get started. If not already implement you have to install a training matrix and train your operators accordingly, to get them qualified to handle all aspects of your operation. Undoubtedly, it may require you to make some investment upfront.

Simultaneously with the training of your operators you will need to standardize every process step in your production. By doing so you will reduce the amount of training and therefore qualification needed in order to fulfill the requirements for the single process steps, as they are broken down to the simplest operation.

Clear and simple “Standard Operation Instructions“ (SOI) will be required to explain the operation and guide operators through the qualification and later performing the process step. By this due to variation of operators in a assembly cell they can get fast into new work requirements. In addition the supervisor can always react faster as the standard process is always described and if deviation occurs the cause is faster detected and eliminated.

So the cons can be wrapped up as investments upfront. Paying all of the expenses at the initial stages for the purpose of integrating and incorporating Shojinka will prove to be worthwhile in the end. There is no denying that your workforce will ultimately become significantly streamlined and that Takt Time of goods will be flexible to the max.

Hansei

Japanese term meaning to accept your personal responsibility for your own mistakes and the will for improvement. The Hansei Assessment can be seen as deep personal reflection.

The Japanese term of Hansei has the meaning to acknowledge your own mistake(s) and to strive for improvement. The term describes your personal ability of reflection and will to do better.

Hansei plays a big role when thinking about the continuous improvement process and specially the part of looking back and reflect of what could have gone better or where you as person did come short and have a potential lesson.

At Toyota, Hansei is a fixed part of their production system. The Hansei Assessment is held to have a deep review or personal reflection. Typically these assessments are conducted during milestones or at the end of a project during the lessons learned part. The results are communicated to the whole organization so that all can profit from the knowledge gained from this process. By this you will support your complete organization from repeating mistakes or even improve existing standards in order to prevent this from happening again.

You see Hansei can be seen as a crucial part of the organizational development and as heavy weight components for the continuous improvement process, KAIZEN activities and standardized work, as in the end it is up to humans to run your organization and we all make mistakes we can learn from.

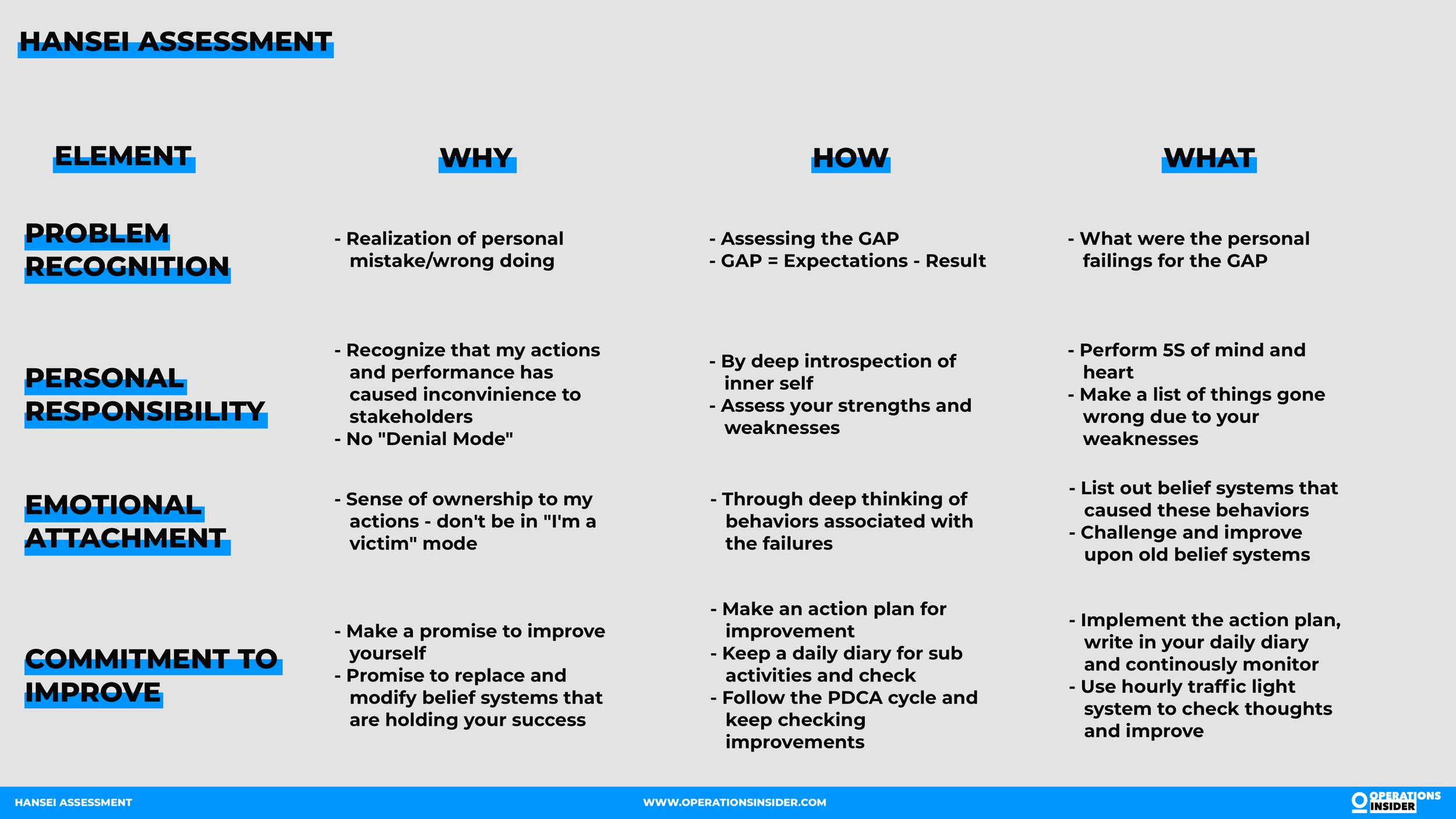

In a Hansei assessment you have 4 Elements to analyze and the questions to find an answer.

Hansei Assessment

Kamishibai Board

The Kamishibai Board helps your organization to visualize and manage recurring tasks in a very simple but effective way.

The Kamishibai Board is part of the visual management in Lean Management that supports you on managing recurring tasks in a way that the status of each task is clearly recognizable by everyone in your organization.

The tasks are listed by their frequency and the responsible persons. The design of the cards can vary, but typically T-Cards are used as the handling is quite easy. These cards contain on both sides the information of each task. One side of the card is red the other one green. RED: to do, GREEN: done. So the color is indicating the status of each task.

By using these two color coded cards everybody in the organization will recognize if all activities are on track or if there is a backlog ahead on performing daily, weekly or monthly activities.

Example Kamishibai Board - weekly tasks with assigned persons

Kamishibai is a Japanese term, to bring it in operations terms it can be understood as mini-audits. The Kamishibai is a great starting point for Gemba Walks mainly in the admin area of your organization but can also be utilized in the service and maintenance department. It also supports 5S activities and assists in checking the continuous improvement actions on checking on standards and improvements during regular meet ups.

The Kamishibai approach has different sections. E.g. a simple planning board with T-cards with a red and a green side, a list of person in charge and a 3C list. The 3C list thereby describes the Concern, defines the Cause and lists the Countermeasures, find a free template (in flip chart format) here.

The planning section has the tasks tank, on the far left side all tasks are stored in holders (T-Cards) or e.g. magnetic cards that are also green on the one and red on the other side. One section further to the right you can implement a matrix with responsible person for each row and all weekdays as column. By this you can easily assign tasks.

Between the organizational and the problem solving part there should be space for the escalation or support needed tasks. It might happen that an assignee is not able to fulfill a task as he/she is in the need of information or active support from a different level or department.

To sum it up. The benefits of the Kamishibai methodology is mainly the visualization part. It gives clear structure and is understandable at first sight. With the Kamishibai you are able to perform so called “mini-audits” on a regular basis that helps you driving the continuous improvement process in your organization and supports you on performing effective Gemba Walks. Instead of heaving some chit chats you can bring information straight to the point and address any issues fast.

You can use the Kamishibai methodology for all kinds of work areas in your organization, e.g. you have control indicators for methods, processes, documents, standards and much more. In the end the Kamishibai helps you to keep the routine of defined standard work procedures as results of KAIZEN activities. If it works congrats, if not congrats - you found something that can be improved.

Implementation of 5S

The 5S Method is a five-level system for the provision of safety, cleanliness and orderliness on the workplace.

If you want the short version just go here. Otherwise we will deep dive in this article on how to implement the 5S methodology in your organization. We will simply follow the 5 Steps and explain the topics.

1st S SEIRI = Sort out all unnecessary objects

Unnecessary objects are all objects that are not needed for the current manufacturing processes (production, logistics, quality, and administration, etc.), that means, defective parts, unused material, material that has been written-off, all spare parts, non-utilized tables and so on

Determine in advance, what is truly needed. This is helpful when dealing with statements such as: “That still can be used“, “That should be useful for something,“ etc.

Remove all redundant objects or at least visually mark them so that everybody is aware that they are to be disposed of

Unused objects should be concentrated in one marked closed area. The decision about those that can not be immediately liquidated, as whether to dispose of them, should be made by the person responsible within 2 weeks

Target: At the workplace are only objects essential for the current work in progress.

Red Tag Campaign

Ask three questions for each separate object:

Is this object useful?

How many of these objects do we need?

Where should this object be stored?

Don‘t support others in searching for excuses. Be fair – mark objects that should be removed in all divisions of the company

Don‘t compromise! When in doubt - the rule applies: Get rid of it!

If there are suggestions for improvement of the current manufacturing process, it is possible to “red tag“ even objects still in use

Make sure that everybody understands what should be marked and why

Course of action and rules for the “Red Tag Campaign”

Write on the tag why the marked object is not needed (Example: Surplus packing boxes; parts stored in boxes are not used any more)

Contact Information about the person who made the decision that the object is superfluous (name and department)

The person responsible for the object will be informed and their name will be entered on the “Red Tag”, and along with the agreed-upon date of removal (maximum 3 days), the action should be recorded (Example: The employee who recognized that the boxes are not used anymore, will inform the warehouse attendant and will appeal to him to verify if they are really not of use anymore. If it will be discovered that the object is still in use, the “Red Tag” will be removed. (For instance: The warehouse manager finds out that the boxes will be used to store other parts very soon)

If the object will be classified among the superfluous, it must be removed within three days by the person who has the responsibility for this area. (For instance: Redundant storage boxes - person responsible for the warehouse). Afterwards the “Red Tag” can be liquidated

Objects can be “Red Tagged” only in working areas of ones responsibility. The Shift Leader can issue “Red Tags” in the entire area they are responsible for

The “Red Tag” will be filled out by hand and attached to the unwanted object.

Examples of unwanted objects:

1 Defective products

Faulty parts

Rejects

2 Unnecessary objects

Unused empty packaging

Personal objects (on undefined places)

Unneeded assembly sets

Unused material (remaining bundles)

Unused tools, auxiliary and production material

Inventory no longer being used

Surplus of manufactured components

2nd S SEITON = Clean-up and correct arrangement of needed objects

After the removal of all unnecessary objects, remove all uncleanness, as new organization of areas for laying down objects or their storage can start only after everything is clean

Each machine and each tool must have its designated place.

Thoroughly deliberate about where you will store material, tools, and equipment

Use colored markings (for instance stickers) to designate areas, cabinets, shelves, cupboards with shelves, important places, direction of work procedures, etc.

With each object ask three key questions: Where? What? How many?

Permanent storage of objects in

Targets:

A place for each object and each object in its place

Visual control and expedient detection of deviations

Proper storage of all needed objects in the right place. These objects can then be found and used whenever needed

Every thing has its own place and after its use is always returned to its place!

Think about color markings on the floor e.g.:

Yellow = transportation zone

White = raw material

Green = finished goods

Red = closed area/NOK parts

3rd S SEISO = Keeping the workplace tidy so as to achieve the already established standards through 5S

The purpose of the cleaning action is to remove all contamination from the workplace and to maintain it in order.

For this purpose a cleaning schedule will be formulated that will determine what is to be cleaned, with what, and by whom

If you discover any shortcomings or abnormalities during the cleaning process – mark them down

All employees of the workplace / work area will participate in the cleaning process

Keep records of the cleaning process, display visually “Red Tags,” as well as the clean-up time schedule of your workplace. Display results

Define responsibilities with consideration even to the smallest work sections

Be effective. Even a five-minute cleansing action can achieve a lot

Targets:

Cleaner and safer workplace

Achieving the already established standards

Cleanliness

Cleanliness at the workplace must be observed, because a clean workplace is essential towards quality and safety at work

If the workplace is not dirty it is not necessary to clean it

Any kind of uncleanness and any kind of untidiness will be visible thanks to the initiation of a regular cleaning process – for instance, dusting, sweeping, and waste disposal

Continuous usage of equipment

Removal of all uncleanness and untidiness

Prevention of working accidents

Cleanliness means controlling, which implies that when cleaning a certain workplace, also check the state of the machinery, equipment, and working conditions

4th S SEIKETSU – Establishing regulations for work standards

SEIKETSU has the greatest importance of all 5S Steps.

With this 5S Step the main focus is on three aspects:

No unnecessary objects

No messiness and

No uncleanliness

Visual control is the first step towards discipline. The ideal workplace is that with which any eventual problems can be detected at first glance – any corrective measures can be immediately implemented

Use control lists to control the 5S standard and to identify deviations from the defined 5S standards

Conduct 5S audits with consideration to the situation on the individual work place. Attempt to identify deviations from the 5S standards

Ask yourself “follow-up questions”, as for instance: Has the mess been cleaned up immediately? Is it clear who is supposed to do the job? Can the clean-up be done quickly? - and others

Targets:

Securing the adherence to the 5S Standards

Increasing the team responsibility on the work place

Schedule of everyday clean-up

5th S SHITSUKE – Adherence to the Work standards and continuous improvement

Discipline, namely, adherence to work standards is basically a question of personal attitude. For it to be easier, various teaching aids are used, e.g. Courses of the 5S Basics

Use photographs, single-topic lectures, video-programs and presentations

Constructive criticism is the foundation for proper 5S training

Take pictures to document the status quo before and after

The Team Leader functions as an example to the team. During his work he should focus on the goals of 5S, he should strive for a continuous improvement of quality and in this direction aim his training activity also

Define together the measures for improvement and how to realize them.

Regulations are better than criticism and a system is better than regulations

Targets:

Promotion of this know-how in the entire company from top-to-bottom

Well-organized work places that require only the minimum attention

Kaizen Manager

Kaizen Mangers are the people in your organization who initiate changes within your organization or support departments on the path along the continuous improvement process (CIP).

Kaizen Manager (Change Agents)

Kaizen Mangers are the people in your organization who initiate changes within your organization or support departments on the path along the continuous improvement process (CIP).

Change Agents are the key players in your organization to integrate new processes or improvement actions and simultaneously stabilize departments throughout a change or transformation process.

When talking about a Kaizen Manager or Change Agent he/she has the following duties with the support of the Change Leader:

Support the change process by defining the program, participants, selecting suitable processes and defining the targeted state

Set individual targets for responsible/affected persons

Support responsible persons for each individual improvement process through coaching or scheduling exchange rounds with other key players. (To stay on track)

Support the onboarding process for new people to the program

Support on the transformation process from learning to actually doing

Coordinate and support further expansion within departments

Support on the transformation process of organizational culture

Challenge status quo with fundamental questions on existing procedures

Work closely with the heads of departments to anchor the new improvement culture across the complete organization

What ever it takes, it has to be clear that a sustainable change culture can only be established if all of your mid and top mgmt. themselves drive the integration of all their direct reports. The Kaizen Manager is the pure supportive function in the role of an internal consultant to guide the process.

Makigami

With the help of a Makigami - administrative processes are recorded and redesigned.

The Japanese term Makigami is developed out of two. First the MAKI (yeah like the Sushi) meaning roll or rolled and KAMI meaning paper. Before you go wild, in the word combination you write kami with “g”. So the question that rises is: What you do with a rolled paper? You use the Makigami to draw and redesign administrative processes. Like with all Lean or Opex activities, once the process is visualized with the help of a Makigami “value-adding” and “non-value adding” activities are marked. On the bottom of the Makigami you will find a time axis which shows the operating time and the pure value adding time.

With the help of the Makigami process analysis, the process is always viewed from the perspective of the process itself, never from the perspective of the employees. This has to be clear also for the waste attack activities in the process. With the Mantra of OPEX: the central question that must be brutaly honest answered: Is the customer willing to pay for this process step/activity? Is this what you are doing adding value to the final product or service?

After you recorded the current state of your process you start to redesign it by asking yourself permanent the following question:

What should the ideal process look like?

Take your planned future development and corporate vision into account to make sure you are not running in the wrong direction.

QRQC

The QRQC can bee seen seen as a general management attitude to solve any kind of problem at the place where it occurs.

Quick Response Quality Control

The QRQC can bee seen seen as a general management attitude to solve any kind of problem at the place where it occurs. Closely related to Gemba Walks. With QRQC the main focus relies on the so called “Three Reals”. The three reals aims to guide you firstly to think about the real place and real time (Gemba - or originally “gen-ba”), the real part (“gen-butsu”) and to have a focus on the reality (“gen-jitsu”)

Having a functioning QRQC systematic installed supports the greater target of smooth production by:

Decrease of Cost for Quality

Decrease of Scrap Rate

Decrease Cost of Product

Less line Stops

Quick Response on customer Quality Claims

Increasing the Quality Level in general

Increasing the turnover of inventory

Increase of throughput

As with all Lean or Operational Excellence activities you will need the support of coaches and management level. Implementing a standardized procedure on how to react on customer claims and internal failure rates needs C-Level support to promote and to walk the talk. The baseline of problem solving is and always will be the discipline to follow the complete structure and process of standardized problem solving.

Important as the problem solving itself, is in the end the transparency and promotion of solutions as well as clear communication and sharing of the gained knowledge through Shop Floor QRQC initiatives to be seen by the whole organization. Best way to do so is visualizing important information of the closed issues, such on Shop Floor Boards or at work stations themself.

Andon

Andon is a crucial part of visual management on the shop floor that gives a signal that indicates if and where there is a problem.

Andon is a crucial part for the visual management on the shop floor that gives a signal that indicates if and where there is a problem. Typically indicated with a traffic light signal red = failure mode, yellow = non-conforming performance and green = normal operation mode.

The methodology of Andon as part of the shop floor management, is to show the current operating status of a machine or a production line in a way that everyone can see and understand it immediately. As typically in Lean Terms Andon comes from the Japanese language and means paper lamp or just lamp.

Going along the Andon-Systematic there is to mention the Andon-Cords. The cords are used by operators to activate the lamps by either tear the cord or more likely nowadays pressing the corresponding buttons, which are attached above the production line and are easily accessible for the operators hanging downwards or as button attached at the work station.

If a non-conforming condition occurs, the yellow Andon signal initiates the support so that the problem that has occurred can be remedied immediately with additional supportive functions, such as maintenance. In worst case it is also possible to stop the complete production (red signal) until the problem has been solved or at least suitable countermeasures are in place.

An Andon has three main functions:

Visualization of the operating status of a machine/assembly line

Possibility for the operator to report an non-conforming condition and escalate it using a defined escalation process

Production or belt stop, so that no non-conforming products or components are passed on to the next process step

Old fashion Andon Board

The clear display of the operating states of several workstations was used quite early in the development of the Andon systems. The godfather of the TPS, Taiichi Ohno once described it as followed: "When one looks up, the andon (the line stop indication board) comes into view, showing the location and nature of trouble situations at a glance."

In the course of time, the Andon board has increasingly developed into an information board for all employees involved in the process. They display status information regarding the current situation in production, such as the number of units produced per day or per hour, the degree of delivery reliability to the customer or the cumulated amount of backlog. In this way, all process participants are aware of the current situation and can act accordingly.

Andon Boards nowadays

OCT

The Operator Cycle Time is the time an operator needs to fulfill a dedicated process step, including loading and unloading but excluding waiting time.

The Operator Cycle Time is the time an operator needs to fulfill a dedicated process step, including loading and unloading but excluding waiting time.

The Operator Cycle Time is measured from when the operator starts his/her process and is stopped when he/she is ready for the next workpiece (no matter if it’s there or not). Yes I said that the OCT is exclusive waiting time, but not exclusive the waiting time within the process itself. That means if the operator is waiting for a machine, he/she loaded, to finish the operation and unload the workpiece, this waiting time will be included in the OCT.

Most of the time OCT can be seen as the same as “cycle time”. The main difference comes from the waiting time an operator has, while a machine is running a process and the operator him-/herself would be ready for the next piece. This means in the end the OCT is always shorter as the CT. Going even further this means that the OCT can be shortened when installing a HANEDASHI device that autounloads the workpiece after the operation.

As with all lean management activities and targeted increase on productivity and flexibility time is on focus. But make sure to understand the process first, before running improvement actions you have to know what to improve.

OTED

One touch exchange of a die.

Depending on your field of industry the defined times to perform a changeovers varies between 1.5 and 1 minute.

To run OTED successfully following actions are required upfront:

Reduction of adjustments needed down to zero

No fastening with screws needed

100% positive locking between die and tool carrier

Proper fitting methods

Separation between tooling and function

The target is simply explained: The exchange of a die is done with one single motion.

When having a look at the development of improving changeovers the first step is to implement the single-minute exchange of a die (SMED). SMED helps you in the beginning to figure out how to perform the changeover with less motion. OTED is then the high level of changeovers. As mentioned as SMED can be also understood as single digit exchange of a die, yes this means everything under 10 minutes is SMED, OTED stands for the ultimate target. Through continuous improvement actions on SMED you are striving to reach the state of being able to exchange tooling in the takt of your line with one single motion.

In the end with OTED you have to deal like with all the other Lean Tools, don’t just apply it to be cool and “lean”. If it doesn’t make sense for your operation or process don’t do it. But when you decide to strive for OTED and you and your team are convinced by the promised improvements , make sure to understand the process flow first then take action.

Production Diary

The production diary, as part of the shop floor management system, defines a shift based weekly forecast incl. upcoming tasks for mgmt., supporting functions and is openly displayed on the shop floor.

With the help of a production diary, based on a pre-defined shift planning all other functions and outcomes are planned and tracked. This includes the mgmt. team as well as all supporting functions. In order that everyone is aware about the upcoming week the production diary is openly displayed on the shop floor. With the production diary and the pre-set structure of daily meetings of the shop floor mgmt. all daily activities are carried out. Best known part is e.g. Gemba Walks and the included problem solving activities e.g. A3 or just confirming that all processes run as planned.

With this big part of shop floor mgmt. it is clear that all regular meetings planned along the production diary are set. All other unplanned activities or extra meetings need to be conducted respecting the fixed schedule of the production diary.

Hanedashi

Is a device or means for automatized unload of a work item from one process or operation, providing the correct state for the next item to be loaded.

Hanedashi is called a device or means for automatized unload of a work item from one process or operation, providing the correct state for the next item to be loaded. The Hanedashi principle of automatized unloading and orientation for the next process is often used in automated production systems that operate according to the Chaku-Chaku principle.

When designing a machine according to the Hanedashi Principle, the only manual operation is to insert the workpiece. The processing and afterwards the ejection is fully automated, the workpiece than can be transported to the next machine or handed over to the next operator. Meanwhile, the machine automatically returns to the initial position where it can be reloaded.

The conclusion of the Hanedashi Principle: Humans are better for loading and machines are better for unloading. It is that simple to knock it down.

7 Steps - Problem Solving

The 7Steps problem solving is a standard analysis method.

The 7 Steps problem solving is an analysis method that is typically used in the 0miles major customer complaints and warranty complaints: when risk analysis is necessary. The single steps are as follows:

Problem description / risks on similar products and processes

Define containment actions

Data collection (grasping the facts / failure mode analysis)

Identify possible Root Causes

Implement corrective actions

Evaluate effectiveness (Tracking Chart)

Lessons Learned

Root Cause Analysis is one of the crucial and basic requirements in a quality system for continuous improvement. Its target is to recognize a deviation and its origins, resolve the issue so that it is not recurring and improve the quality of the product or processes. Root Cause Analysis always depends on time if you observe a deviation start asap your RCA-activities as no problem should be allowed to grow.

To gain a better understanding let us describe the 7 Steps in more details

1 Problem Description:

Capturing the deviation - Ask the following questions:

What is the problem? (symptom; use illustrations to describe as clear as possible)

Why is it a problem? (content of complaint / definition of problem statement)

Where was it detected? (location of occurrence/Area of the product or process)

When was it detected?

Who detected it?

How was it detected?

How many defective / suspect parts?

Can the problem appear on other products or processes?

Other parts

Generic parts

Opposite hand

2 Define containment actions:

Use a Tracking Chart to list your counter measures

Track how many defective parts have been detected

List in Pareto format what kind of failures have been detected

Put in containment actions and responsible person

Define when the actions have been planned and implemented

Data collection (grasping the facts / failure mode analysis) get and check the valid documentation:

1st part release

Maintenance records

Poka Yoke checks

Process parameters tracking charts

Work Instructions (SOI)

Control Plan

Drawings

Production information

Error collection sheet

First Time Through Report

Boundary sample

Ok part available

Ask the following questions:

Was it the correct process? - How should it be?

Was it the correct tool/fixture?

Was it the correct part?

Has something changed in the process?

Has something changed in the product design?

Is the process in control?

Do all product components meet quality requirements?

Collect pictures, evidences and records to support analysis.

3 Build the ISHIKAWA Diagram

List the problem to be studied in the "head of the fish".

Use an idea-generating technique (e.g., brainstorming) to identify the factors for non-conformance and non-detection within each category that may be affecting the problem and/or effect being studied.

Repeat this procedure with each factor under the category to produce sub-factors. Continue asking, "Why is this happening?" and put additional segments each factor and subsequently under each sub-factor.

Continue until you no longer get useful information

To learn more about the Ishikawa – read this article.

4 Identify the Root Cause

Analyze the results of the Ishikawa after team members agree that an adequate amount of information is provided for each major category. Do this by looking for those items that appear in more than one category. These become the “most likely causes".

For those items identified as the "most likely causes" the team should reach consensus on listing those items in priority order with the first item being the most “probable" cause. A useful method here is to allow each team member to allocate 3 points to their chosen root causes. The root cause with the most points can be taken for further analysis using 5 Why.

Once the most probable causes are drawn explain failure mechanism focusing on 2 aspects:

Cause of non-conformance

Cause of non-detection named

Use the 5 Why method for looking at the problem

5 Possible Actions

Create an action plan with countermeasures for non-conformance and non-detection to eliminate/minimize the effect

Do not forget about due dates and responsible persons (preferable only one person for one action)

6 Evaluate the effectiveness (Tracking Chart)

Put in permanent actions (+ responsibility) and make clear when the action has been planned, implemented and stopped. Track how many defect parts have been detected. After implementation of permanent actions remove containment measures only if there are no defects detected any more.

7 Lessons Learned

Visualize BEFORE and AFTER (KAIZEN REPORT)

Specify what needed to be documented (e.g. Standard Operating Instruction (SOI), etc.)

Grasp what you’ve learned (improvements in working and detection process)

Think about potential applicability in your organization (review similar design, equipment, components, processes, material or manufacturing processes).

Share what you have learned within your organization.

Some of the benefits of the Root Cause Analysis process are that you will identify which procedures will need to be changed, which documents describing those procedures will require modification and who will need to be trained or re-trained.

Finally, don’t forget that the root cause analysis process must lead to an effective corrective and preventive action plan. One without the other would mean that there is no certainty that the issue is solved and that the failure cannot reoccur.

If liked this article give it a thumbs up.

5 Why

The 5 Why methodology is a well known part of the root cause analysis. Key is to ask five times in the row – why?

The 5 Why methodology is a well known part of the root cause analysis. Key is to ask five times in the row – why? It is not the only way to determine the root cause(s) of problems. Just to mention that it usually comes together with an ISHIKAWA analysis. If you want to get deeper into problem solving including ISHIKAWA and 5Why we recommend you the article taking on the 7Steps approach.

The practice of asking why five times in a row whenever a problem occurs supports you on identifying root cause(s) and to determine effective counter measures that are developed through the process of 5Why. Then it is a simple part of PDCA to develop and implement effective measures.

To be able to steer a wide product portfolio, survive the competitive pressure and at the same time satisfying your customers with a high quality product at a reasonable price can be a tough game. Most of the time you don’t have enough time to run the complete product development cycle, do your validation and verification… The end of the story is that you start production because you need to deliver – which automatically leads to mistakes in running daily business. Therefore, the simple method of 5Why can be used to support, not only, your quality department to get faster to the bottom of problems.

The solution for a problem is not always easy, sometimes the root cause is hidden. Therefore the method is an important element of the root cause analysis. One tries to get to the root of the problem step by step with why questions, because one assumes that several causal connections interlock. The system is easy to explain, but there is a lot behind it. If you really take the time to ask the questions carefully and discuss them, the results are extremely profitable.

You should go through these steps of the 5-Why method. Describe your problem as detailed as possible. As more facts you have, you are faster on getting to the bottom of the problem.

What is the difficulty?

When did it first occur?

How often does it occur?

Is this failure randomly coming or reoccurring in a pattern?

Can you repeat the failure?

What is the effect of this failure?

and so on….

It is very important to get a fast idea of the situation on site. Take the Gemba Walk as great opportunity to talk to the people who are actually involved and to see it with your own eyes instead of guessing from your office.

Avoid making assumptions at this stage - you may draw the wrong conclusions.

Keep calm and try to understand the complete context first.

Understanding the context is where the 5-Why method comes in. Gradually ask why questions in order to get a feeling for the interrelationship of effects. This works for many areas of the company, in production, but also in your private life.

Example:

Problem: I miss all the fun part with my kids…

Why do I miss so much? - Because I’m not often at home.

Why am I not often at home? - Because of my position at work I have long working hours and business trips.

Why do I have long working hours and business trips? Because I can’t get my work done in 8 hours and bad in delegating work.

Why can I get my shit done in 8 hours and miss to delegate things? Because I’m sloppy in prioritizing and time management and don’t trust others.

Why can’t I prioritize my activities and don’t trust others? Because I don’t have the information needed to do so.

Reverse conclusion: If I’m not getting the necessary information in a certain amount of time in an acceptable quality I’m not able to steer my employees but also miss the time with my kids.

Sometimes 2 questions are necessary, sometimes 8 or even more to bring you to the “right” conclusion. But don’t give up half way.

Develop appropriate counter measures:

What contributes to solve the problem and who can implement which measures? How long will this take and what consequences will the implementation have?

First: I should try to have set timeframes with my kids which are holy and untouchable.

Second: I should define what information for me is necessary to run my company.

Third: According to the defined Information I train my employees what I need.

Fourth: I implement a clear systematic approach that I have all information latest at 11:00.

(DING DONG - Sounds familiar? BINGO — Shop Floor Management with a functioning meeting cascade.)

Keep the wheel spinning!

No matter what – before start implementing ad-hoc whatever you find best – take your time to identify what actions contribute to a real long term effect, what effects it will have on other areas, etc. Nothing worse than if you think you are doing something great but in reality you make it even worse.

The cycle of questions is often interrupted too early. The real cause is then not really eliminated and after some time there are repeated difficulties.

You can test it: If the reverse of your assumptions works, you are probably at the end of the causal chain.

As mentioned in the beginning another way is the ISHIKAWA diagram

Just keep in mind that not like with the ISHIKAWA the 5 Why only leads you to one cause for a problem. But as always in life there can be more than just one that leads to an effect. Therefore, the combination of 5Why and ISHIKAWA gives you the best approach to determine causes. It will allow you to represent several major and minor causes that can contribute to the solution.

Get the big picture with an ISHIKAWA drill it down with the 5Why.

Affinity Diagram

The affinity diagram helps you to organize a large number of ideas into logical categories and natural relations.

So you have a large number of ideas and need to organize them. The affinity diagram is the perfect fit to get the job done and to structure your ideas into their natural relationships. Basically the affinity diagram describes a structured outcome from a brainstorm session. You can use it to generate, organize and consolidate information related to a product or process, complex issues or different problems. After the brainstorming session you should group the ides according to their affinity or similarity. This idea creation method was created in the 1960s by Japanese anthropologist Jiro Kawakita.

When should you use an Affinity Diagram

The typical use of an Affinity Diagram is when you are confronted with many influences or ideas in a state of chaos. Sometimes a problem seems too large or just too complex to understand it at first sight. Or you simply want that the whole team has a common understanding of a topic.

Usually you are confronted with this situation:

After a brainstorming session

When analyzing open questionnaires, such as survey results

When collecting and organizing large sets of data

When trying to develop relationships between different ideas

Or trying to reduce input to a higher level of categories

Typical process of developing an Affinity Diagram

The Affinity Diagram process gives a group a direction to go beyond normal creative thinking and defines categories to get all thoughts in order. This technique opens the doors and shows relations in between the whole organization which is typically separated due to department silo thinking. The Affinity Diagram has no limits, so don’t be irritated if you have to deal from 20 up to 400 items after a session. It is a starting point not more not less.

Materials needed: Sticky notes or cards, marking pens, and for sure a large surface (wall, table, or floor). Brown paper is a good way to start.

Step 1:

The brainstorming

Write down all ideas on separate sticky notes or cards.

Spread the sticky notes or cards randomly all over the brown paper

Gather all participants around the brown paper after all notes are taken

Hint: Use big markers so it easy to read for everybody from distance. Make key statements on the notes don’t write an essay.

Step 2:

Try to sort all ideas that are related in some way and group them up

Try to find relations between these several ideas

Let the team sort ideas

Try to find 8-10 relation groups

Repeat until all ideas are grouped

It is fully reasonable that there might be an idea staying by itself or that team members will move an already grouped note again to another. If an idea belongs in two groups, make a second sticky note or card.

Hint: In this step it is crucial that there are chats going on, it has to be done in silence. Focus is on sorting and grouping ideas. Headlines are done afterwards! Not upfront!

Step 3:

Open discussion with your team.

Try to find common categories and define headlines for each group together with all team members. Discuss what you see or why members see an idea in a different category. If necessary, make changes and move ideas between categories. In the end, when all ideas are grouped in the consent of the whole team, define the headlines of each group. Try to find a catchy headline that describes the meaning of the category in short.

Hint: Cards with the headline should be in a different color than the rest and should be self explaining about the group.

Step 4:

If reasonable, try to define “mastergroups” of several “subgroups”.

Sort all ideas to their identified category by placing all ideas under the “headline card”.

Hint: The sorting is done by gut feeling, not with a scientific approach.

SIPOC

SIPOC can be used to clearly define process steps within a process chain.

SIPOC is a > Six Sigma tool that summarizes an entire process at the start of an improvement project. SIPOC can be used to clearly identify process steps within a process chain. A SIPOC diagram is only a snapshot of a process. Each of the letters in SIPOC represent the names of the columns in the table:

S – Supplier, I – Inputs, P – Process, O – Output, C – Customer.

The SIPOC method has its origins in Six-Sigma and is used there in the definition phase of a project. To have it summarized see the following Infographic:

By applying this method, it is possible to quickly gain an overview of all the main elements of a process to be examined, even before more in-depth details are worked out.

SIPOC is a very simple and at the same time very effective method that can also be used in various situations in the lean management context.

Possible applications of a SIPOC can be:

Starting a KAIZEN workshop in order to create a common basic understanding.

To achieve a quick overview (top level) for subsequent process optimization

Simple type of documentation for existing processes

Identification of important process participants (who must attend the KAIZEN workshop)

Definition of the process steps to be investigated within a process chain

How to use SIPOC:

The SIPOC method can be used in many different forms, such as Excel spreadsheets, handwritten tables on flip charts or brownpaper versions using cards or post-it notes.

The easiest way is to start by listing the process steps. No more than 5-7 process steps should be listed, since the SIPOC method is not about carrying out a detailed process analysis, but only about gaining a rough overview.

It often makes sense to note down on the process card those departments or persons who carry out the process for the respective process steps, so that it can be recognized immediately who is responsible for the process.

Input: which input factors are necessary to perform the process step? This could be material, information, machines or a service.

Supplier: who provides these input factors? Do they come from an external supplier or from an internal supplier - perhaps as the output of a previous process step in the process chain?

Output: what is produced as a result in the respective process step. These can be material things such as components, assemblies or finished products, or intangible things such as processed information in the form of a document - e.g. a static calculation or an order confirmation.

Customer: for whom the result was actually produced. Make a distinction between external and internal customers. If no customer is found for the output size, it must be checked whether the process step makes sense at all.

Stay Connected

Ad

We want information fast and in a nutshell. We from OI recommend Blinkist* - because it’s simply the best.

* = Affiliate Link