LANGUAGE OF LEAN

The Osborn List

One great tool to support the brainstorming process is the so called Osborn Checklist.

Brainstorming with the the Osborn Checklist:

When it comes to getting new ideas - the so called Osborn List is a great method to steer the process. This creative idea generation technique is named after its inventor, Alex Faickney Osborn. Osborn is also regarded as the father of brainstorming.

The Osborn List is a simple method to support the process for concept creation, it thereby is a comprehensive list of questions about ideas and problems which can be used either individually or in groups. The main goal is to encourage creativity and divergence in concept generation.

The series of simple questions need a point of focus, which can either be an existing solution or a proposed concept to a designated problem. During the brainstorming session writing each statement on a card will help you to structure the approach itself. Randomly take a card while discussing alternative solutions.

When you have your topic, product or process you want to discuss, go through the checklist. The Points are:

What else can it be used for?

New ways of using it? Other use when modified?

Can it be adapted?

Is there anything out there similar to this? What other idea does this suggest? Was there anything similar in the past? What could you copy? Who could you emulate?

How can it be modified?

New direction? Change in color, design, motion, form of shape...? Any other changes?

Can it be magnified?

What can be added? More time? Greater frequency? Stronger? Higher? Larger? Longer? Thicker? Heavier? What value can be added? Duplication? Multiplication? Exaggerate?

Can it be minified?

What can be taken away? Can it be smaller? Condensed? Miniature? Lower? Shorter? Narrower? Lighter? Streamline? Split up? Less frequent? Understate?

Can it be substituted?

Can it be replaced? Who else could do it? Other components? Other material? Other process? Other power? Other place? Other approach? Other time?

Can it be rearranged?

Carry over parts? Interchange components? Other pattern? Different layout? Different sequence? Change cause and effect? Different place? Change schedule? Earlier? Later?

Can it be reversed?

Change positive and negative? What about the opposite? Turn it backward, upside down, inside out? Reverse roles? Turn tables? Turn other cheek? Change shoes?

Can it be combined?

What about a blend, an alloy, an assortment, an ensemble? Can units be combined?

Often the Osborn List is remembered with the mnemonic aid of "SCAMPER" which thereby stands for - Substitute, Combine, Adapt, Modify/Magnify/Minify, Put it to different use, eliminate, reverse/rearrange.

The Osborn List will support you to gain a new perspective on existing ideas, products and processes. Please be aware that the list helps you for improvement sessions but shouldn't be used in the beginning of an innovation process itself.

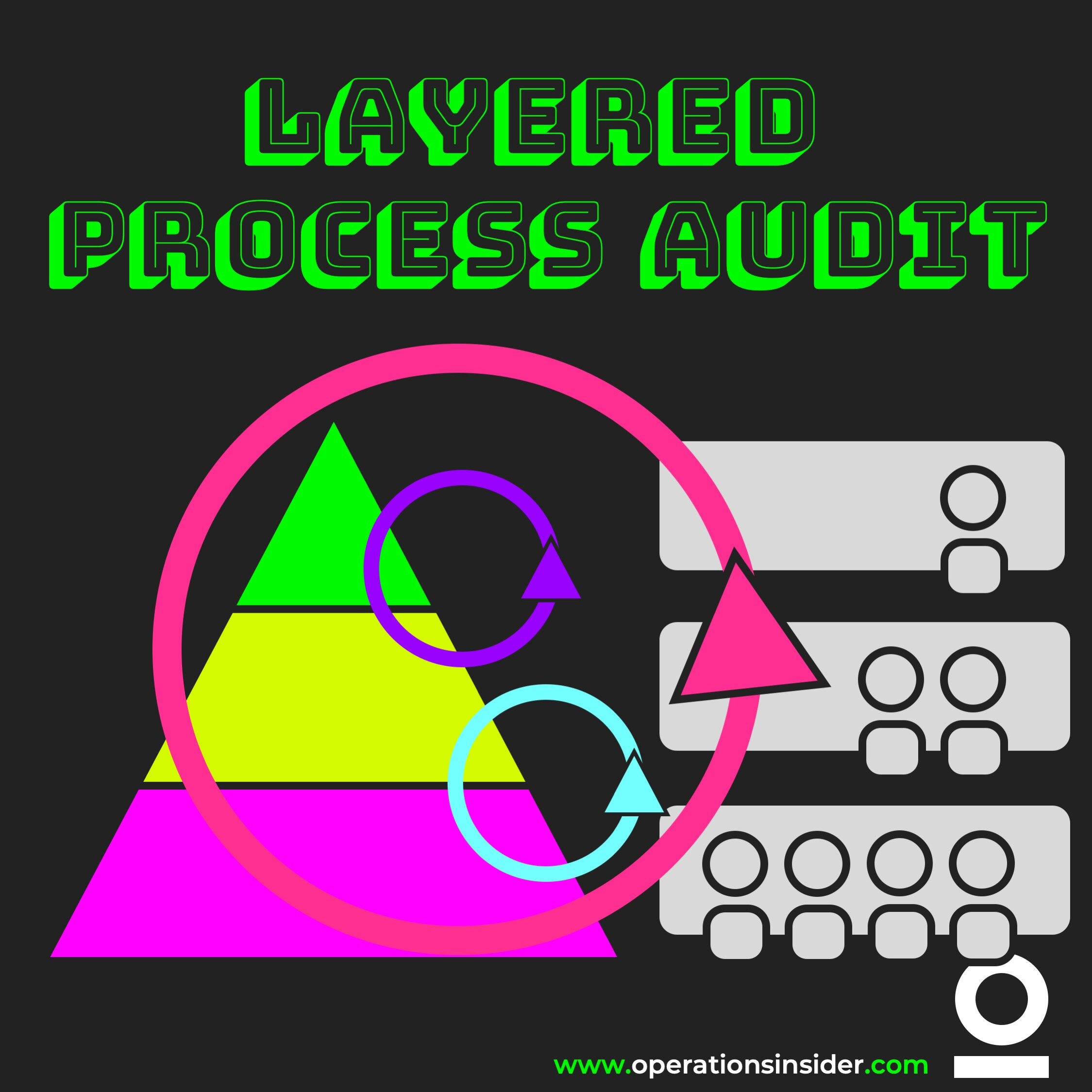

Layered Process Audit

LPA, or Layered Process Auditing, is a quality technique developed for manufacturing management.

Today we will talk about layered process audits.

LPA, or Layered Process Auditing, is a quality technique developed for manufacturing management. When used correctly, LPA brings your organization to improve quality, minimize scrap and rework, plus reduce customer rejections by driving cultural change throughout your company. To gain a better idea and to understand what LPA means we will have a little deep dive.

Layered Audits are a defined approach that devotes time and resources to ensuring that high-risk procedures and error-proofing mechanisms are consistent and functional. Therefore, three important components make up a Layered Process Auditing System:

Full focus on High Risk Processes (HRP) by a list of defined audits

Depending on layer of audit the audit itself is performed from various levels of management

A system of reporting and follow-up to ensure that containment is maintained based on specific needs. But also, to maintain and drive the continuous improvement process in your organization

A full stack of audits

This part of a Layered Process Auditing System is straightforward. Audits are merely a set of questions aimed to investigate machinery or processes. An LPA system's audits should concentrate solely on parts of the value adding process where deviation poses a high risk of producing defective products. E.g. if you have an end of the line quality check station that is measuring crucial parameters or functions that are critical to customers of your product and the calibration is wrong, you are producing in Takt defective or non-conforming products. No need to mention that you should keep an eye on that process. With the help of a proper LPA system you will have the EOL station within the layers allowing containment and corrective action as soon as the station surpasses set tolerances.

Multiple layers of audits comes with multiple layers of auditors

Multiple layers of authority from across your manufacturing department conduct audits on a regular basis, at a predetermined frequency, in an LPA system. For example, once per shift, the Shift Leader conduct an audit that checks the parameters or settings of your EOL-Station. Another layer of management, which may include process engineers, maintenance staff, or even the human resources department, would circulate through the system performing the exact same audit. The sample audit might be performed once a week or once a month by someone in the layer by assigning a number of auditors to this layer and establishing a timetable that cycles through the system's audits. Yet another layer of management, such as the plant manager or even executive staff (the number of levels in an LPA system can vary enormously from facility to facility, depending on your organizations demands and needs). This extra layer of auditors performs the same collection of audits on a rotating schedule, concluding the example audit once a month or once a quarter, for example.

Countermeasures, Containment Actions, Reporting and Improvement Process

In order to have an effective, a Layered Process Audit system you’ll have to combine analysis, measures and improvement process.

If an auditor observes a non-conformance during an audit, the auditor should not only document their findings but also take quick appropriate action to ensure that defective products do not leave the facility. In order to help with the documentation and immediate actions you can use the A3 report and methodology. Simple but effective. You can find it here. Anyway, the findings should be documented and made readily available to management for further analysis. An LPA system is a handy tool for debugging problem areas and identifying areas that are suitable for improvement actions when combined with a strong system for recording and reporting these audit results. A systematic approach will be discussed in the Shop Floor Mgmt. article.

Though Layered Process Audits may be developed to meet a customer or corporate demand, effective LPA systems are built, implemented, managed, accountable to, and owned by your participatory manufacturing management group. A solid LPA system may help you to take proactive control of your manufacturing operations while also enhancing product quality and business bottom line.

Coaching

A coach may not be an expert, but they can be regarded as the technical point of contact and are always asked for their opinion and advice.

There is no denying that the abilities of a coachee to perform and learn are enhanced when they are encouraged by a coach to form solutions to the problems which they are confronting. This is exactly what coaching is. A coach may not be an expert, but for sure they can be regarded as the technical point of contact and are asked for their opinion and advice.

It has now become quite common to see supervisors coaching their employees. There can be a five steps procedure been seen in order to define and achieve goals.

At this point I want to recommend the book written by Anne Loehr and Brian Emerson, "A Manager’s Guide to Coaching" demonstrates how managers or supervisors can help their employees enhance their skills and develop themselves without the need for any additional training.

An employee’s success depends on “aptitude, attitude and resources.” Attitude matters most. In fact, a better outlook can make up for shortfalls in skills or materials.

But let us go back to the five steps of the coaching process.

Step 1: Define the target state

In Step 1 we focus on defining the required outcomes. Get the clarity to define goals or future states. It is proven that those individuals who are clear regarding their goals are most likely to achieve them to those who have not defined their goals in a clear manner. Not having well-defined objectives can result in unpleasant side effects, for instance, preoccupying yourself with details. A successful and effective goal must be created by the coachee itself and must concur with their personal values. It is important to make certain goals a bit challenging, as easily achieving results cannot sometimes prove to be less motivating. On the flip side, it is also essential that some goals must have manageable and realistic partial steps so that, in general, it can be considered as achievable.

Step 2: Status Quo

The main aim in the second step is to identify the delta between the current state and the ideal solution within the structure of the current situation analysis. It is also important to assess the psychological and real cost that comes to light, especially when the client is clung to their current situation. Doing this can challenge the client to provide the energy required for the change. With that being said than just a small amount of time must be spent on assessing the Status Quo, and most of the focus must be given to achieving the desired outcomes. You should not expect any solutions at this particular stage.

Step 3: Costs of Opportunity

At this stage, the client needs to develop feelings for their own resources and their possibilities of gaining control of it: "When you feel resourceful, you feel in control, and when you feel in control, you feel confident." The feelings of control are mainly developed on the basis of the knowledge that there are different options and choices. The coach motivates the coachee to identify various options, by which the probability of determining between the non-action and action would already be recognized and appreciated. For the purpose of identifying different options, brainstorming has proven to be extremely helpful. It involves writing everything which crosses your mind regarding the particular subject in a creative and playful manner without evaluating them. The next step involves coachees opting for the options that look more beneficial and effective. These options are then assessed, and their consequences are analyzed concerning various criteria. Because one thing is certain – every option comes at some cost. Make sure that the coachee is willing to pay it.

Step 4: Taking Action

It is time the coachees make their mind as to which one of the options looks better to them that can help them achieve their goal. At this point in time, the role of the coach is to motivate the coachee to state exactly what they intend to do. It must be understood that it is the responsibility of the coachees themselves to execute the individual steps. The duty of the coach is to identify the signals from the coachee that shows resistance. In such scenarios, it is helpful to refer back to the first stage of outcomes for the purpose of confirming whether the objective and goal is extremely unrealistic or obscure.

Step 5: Review

By assenting to review the plan of action after a certain period of time, a little bit of pressure is applied on the coachee to take action. The critical thing for the success is the genuine conduct of the review rather than just an announcement. It is essential to take the first step in the near future in order to avoid losing the planned actions in the daily activities of the business. For that reason, the momentum for the forthcoming actions can stay consistent. The senior-level personnel or the coach can take help of the review in order to keep the obligation and track the coachee's progress and can also regard it as, for instance, for their own superior. The coach ultimately continues to maintain control, and the coachees becomes capable of achieving clarity regarding their own activities.

Deviation Management

Deviation mgmt. is the ability to identify any disruption to the standard work process and to implement effective counter measures on time.

Deviation Management is simply said the pure ability to identify deviation of a process according to the standard work process and you have a structured approach to tackle that issue.

5 Reasons to work with Deviation Management

Improve compliance and ownership of defective goods or processes

Continuous feedback to operators and staff of their deviations

Structured process for deviation documentation, tracking of counter measures and problem solving

Prioritization of improvement measures

Data collection to engage external suppliers and customers

Demings 14 Points

The 14 principles of good mgmt. described by Deming in his book "Out of the Crisis" can be seen as crucial factors for successful corporate transformation.

In this article we introduce you to Deming's 14 management principles and how they have impacted the Lean Management System.

The person Deming

William Edward Deming was an American professor, engineer, and consultant who studied electrical engineering and mathematical physics before becoming a consultant. He participated in a variety of topics, including statistical process control, systems thinking, and the human psyche. His work as a quality management consultant for Japanese firms was possibly his most well-known accomplishment. As a result, the Deming Prize has been given out to this day.

Nowadays the PDCA-Cycle is well known globally (or Deming Circle). But fun fact – it initially was called the Shewart-Cycle based on his cooperation with Dr. Walter Shewart.

Deming’s 14 POINTS OF GOOD MANAGEMENT

Deming offers 14 principles that he has identified as success elements for effective organizational transformation in his book "Out of the Crisis." Here they come:

To be competitive, set an unchanging business aim of consistent product and service improvement.

Put the new philosophy into practice. We are in a new phase of economic development, and (western) management must adapt to new circumstances.

Stop relying on quality assurance. Quality is not checked at the completion of the process but is built in from the initial stage.

Stop giving out contracts based on the lowest price. Instead, analyze a product's or service's entire cost. For each product, use only one supplier with whom you can develop a long-term and trusting connection.

Consistently and constantly improve the framework for manufacturing things.

Introduce "Training on the Job."

Introduce a fresh leadership style. The focus of leadership should be on assisting people and equipment in doing their tasks effectively.

Take away the system's fear. A culture that freely acknowledges mistakes aids in the identification of root causes, long-term solutions, and hence continuous improvement.

Remove the barriers that exist between departments. Purchasing, development, production, and sales must all work together to identify and address problems in production and service at the earliest possible time.

Employees who want zero errors or increased levels of productivity should avoid slogans and goals. Recognize that many of these goals are impacted by the system rather than by the individuals and that this incompetence demotivates employees.

Employees are no longer held to fixed quotas or performance targets. To make it clear to employees why tasks are important and should be completed, replace them with effective leadership.

Remove any barriers preventing employees from becoming proud of their work.

Introduce a holistic sublimed program that challenges and motivates each person's personal growth.

To enhance transformation, take the services of everyone in the organization.

Getting Demings principles IN THE LEAN MANAGEMENT SYSTEM

According to Deming, the 14 points of excellent management have evolved over time. While in the first point, he discusses relatively small-scale measures that facilitate a company's success, in the second point, he discusses large-scale measures that aid a company's success, the final principles are more basic statements about good business management.

In a lean workplace, we can apply any or all of the principles. Starting with a business vision that explains why the company exists and how it intends to improve over time. Continue with a new perspective on quality. Rather than employing a large number of quality control personnel to inspect the product at the end of the manufacturing process and, if needed, rework the product, the goal should be to incorporate quality into the product, this means that the manufacturing process should be built in such a way that manufacturing errors are avoided from the start (Poka-Yoke) or recognized quickly, allowing for a fast reaction rather than allowing the product to flow to the end of the line. This, of course, necessitates highly qualified staff who can best learn these abilities of immediate quality control directly at the process, as well as a culture that allows for the detection of errors without having to face negative consequences.

The style of thinking in value streams is another aspect of the Deming principles that becomes obvious. It explains how departments must coordinate to predict future difficulties in product manufacturing and services at an early stage. This demands strong cooperation among purchasing, development, sales, and production departments. He also states in principle four that decisions (such as purchasing) should not be made solely on the basis of the lowest offer but should always examine the whole expenses of a decision. What use is a 5 cent purchase price reduction if I have to budget for a 6-month replacement cycle in my warehouse? I have over 5 cents in expenses for storage, transportation, and stalled capital.

Another significant point is the shift in leadership perceptions. Deming is given the following quote:

It is the process, not the people.

Giving employees targets or piecework rates, in his opinion, makes no sense because they have no control over the results, which are decided by the system. Many people would now believe that if there are no goals, nothing will function. The distinction, in my opinion, is in the type of goals. If a corporation has a goal to grow by 10%, you might consider how to improve the system to meet this goal. You don't just hinder all of your employees' goals by 10%; you think about how you might reform the system.

Deming probably assumes that an employee is always prepared to give his all and that management is only demotivating him because it sets expectations for him that are unachievable in the current system. He goes on to say that staff wants to learn more and are always looking for ways to improve. This is a viewpoint that I can understand. When I consider the many employees I've met, I'm struck by how willing the young employees are to give their all and go hungry. Employees who have been disrupted for a long time by "the system" now only do what is necessary and seek challenges outside of work because they are not challenged or motivated at work.

I can only advise everyone to review the 14 Deming management principles again and again and to ask themselves which of the concepts are continuously followed and which are not.

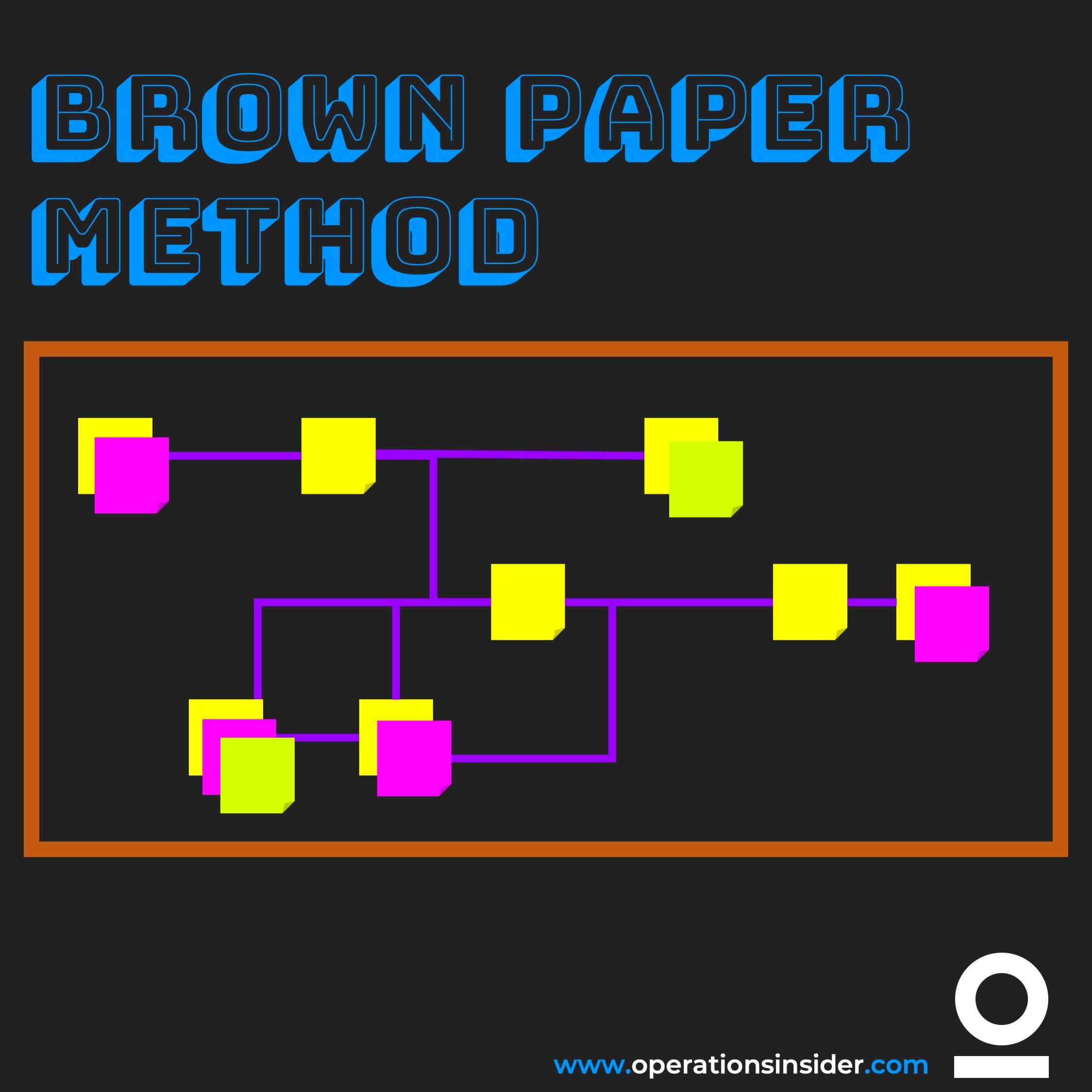

Brown Paper Method

The Brown Paper Method is a practical tool to develop or improve process management in your organization.

What is the Brown Paper Method?

In this article we want to talk about the Brown Paper Method (BPM) in the context of process management.

The Brown Paper Method is an easy to use tool for process development or management for your organization. During a workshop processes are drawn on a large piece of paper (typically from big brown paper roll sticked to a wall) and then analyzed.

Important: Draw the process as they really are not as you think the are. Do a Gemba Walk before this session.

So let us take it as a tool for process management. To be able to understand processes and procedures in your organization and to find out the weak points of them, it is depending on details. Getting those details can be tricky as they might be hidden in the process or in your employees minds and not always so obvious. As mentioned take the Gemba Walks and have a close look on the processes because it usually comes with a taste of complexity. With the Brown Paper Method you then have a simple tool to visualize the complexity in a simply way.

The Brown Paper Method is a pragmatic and result-oriented approach for process audits, presentations or analysis. It is based on a workshop where all involved persons of a process come together in person and collect their findings and doings on brown paper and draw the big picture of the process in total. Through the discussions, that will appear during the workshop, details will be pointed out that matter and defects or weakness will be described and visualized.

With the BPM, the actual process is collected, visualized and analyzed. Target processes can be also developed together. With the Big Picture of the process on brown paper all becomes clear for those involved and the tricky parts of the process are worked out and presented.

Based on the findings of the initial workshop the results are taken to the next level of process modeling. This includes the definition of the target process, implementation of automated workflows and process optimizations.

The process representation on the wall covered with brown paper can contain the following process characteristics:

What triggers and ends the process

Single process steps

Events

Suppliers and customers

KPIs can be important for the process flow (Defect rates, process times, etc.)

Process Input such as raw material, semi finished goods, pre-assemblies, toolings but also information and data such as reports or KPIs

Output and outcome such as finished goods or services

Employees actually executing process steps in the process flow

Employees that have an indirect influence on the process

Other teams or departments related to the process

and so on…

For the upcoming analysis following parts of the brown paper are discussed, additional information added and highlighted:

Critical activities that have a direct impact on the final result of the process including costs and time

Missing or missleading inputs such as information or defective parts

Wrong process steps that are distort the result

Incorrect or missing process step outputs

All potential to improve the process e.g. Kaizen activities marked with a KAIZEN flash

Which of these characteristics finally are listed in the process representation is up to the team as well as the weighting of each. This will then prioritize the potentials identified and when they will be tackled.

Lighthouse Project

When talking about Light House Projects this means nothing less than that a small sector of your organization e.g a department is already turned around.

When talking about Light House Projects this means nothing less than that a small sector of your organization e.g a department is already turned around. By that we are talking about living already the ideal state, that you defined for the complete organization.

Processes and structures can be seen as guidance for your organizations’ lean journey. It provides directions, shows what is possible and therefore is the kickstarter for a successful roll-out as people can convince themselves with their own eyes.

Just keep in mind that the lean journey with its process of continuous improvement is never over. The pioneer has to lead the way.

Continuous Improvement Process

The continuous improvement process is a method to continuously improve processes and procedures in companies or organizations.

Well known, not only in the lean world is the continuous improvement process (CIP). As it says it is a methodology to continuously improve your processes and procedures in your organization. In short = there is always something that can be improved. CIP is not only a saying it is a mindset and should be deeply anchored in your organizations DNA. Therefore it is a must to be lived and demanded by management as well as to be trained and implemented. As per definition the continuous improvement process has no ending it follows the cycle of PDCA over and over again. The basic principle behind CIP is to consistently observe and analyze your processes, take in consideration employees ideas for improvements, implement those and reassess the results if they are according to planned outcome.

Where das CIP come from: A short excursion in history.

In the 1950s, Japanese companies, best known Toyota, started to integrate the "KAIZEN" philosophy of life in operations. The Japanese word KAIZEN stands for "change for the better". To sum it up it means the continuous improvement process by small steps, every day. The ultimate target above all is to reach the highest customer satisfaction possible which guarantees economic success and is achieved by highest quality of goods and services. So they have to be constantly improved. Just think about the KANO - Model.

From the 1980s, European and American car manufacturer started to adopt the CIP methodology to increase their quality and by this their performance of finished goods.

Since the 1990s the CIP methodology made its way from the shop floor into the offices and has a straight impact on an organizations culture. With the so called PDCA cycle it is a never ending process and supports your whole organization on the path of sustainable growth.

Nowadays it is even part of the ISO9001 that defines the continuous improvement process as one of the "seven principles of quality management".

How to apply CIP

As discussed, CIP means improving through a consistent path of small following steps. Basic prerequisite is the ultimate will of your organization's management and the involvement and motivation of all employees in your organization. Focus on customer satisfaction > What is the customer willing to pay for? Everything that has no value for the customer must be seen as waste and has to be eliminated.

In real life organizations take the CIP approach to conduct regular audits by the Lean/Opex-Team. They analyze current issues or challenges and make suggestions for improvements. Typically the following approach can be seen as a rough guideline.

What should be improved?

Define the process, area or procedure

How should it be like and what is it like now? > Define the Delta

Numbers cracking > Go through the figures, actual and target state.

Describe the deviation or problem

What is the outcome by this deviation?

What are the costs of the deviation? Loss of quantity, rework, etc.

What is the root cause of the problem?

Analysis

What are the potential solutions?

Idea and Solution Mgmt. through teamwork and brainstorming sessions

What solution is the best?

Evaluation of the best solution defined

What measures need to be taken?

Cost-Benefit analysis

Results are presented to decision makers

Defined measures are adopted

Who does what, with whom and at what costs?

Measures are implemented

Verification of effectiveness through KPI tracking

If necessary re-evaluate measures to meet targeted outcome

You see, the methodology is very close related not to say a spin off the PDCA cycle.

The endless, repetitive PDCA cycle basically means permanently observing the processes, analyzing bottlenecks and weak points, develop solutions for improvements. To get a better understanding of PDCA read the article here.

In short:

Plan

Recognition of improvement potential, analysis of the current situation, development of improvement measures

Do

Implementation of defined measures

Check

Check the effectiveness of implemented measures with predefined KPIs

ACT

Constantly monitor and review the improvements through audits or reporting. When expected level of improvement is reached adjust the standardization to new level. If you failed on the expected outcome restart the PDCA cycle.

After the PDCA cycle is finished your area of improvement focus will change. E.g. your bottleneck process will move along the complete process.

True North

"True North" - a concept that plays a key role in the journey of lean management and the road of improvements.

"True North" - a concept that plays a key role in the journey of lean management and the road of improvements.

The principle of the true north goes back to the beginnings of the Toyota journey and means nothing less than the direction go for in order to reach real operational excellence.

True North defines the scope of your journey and the boundaries where you want to take your organization to the next level or where you want to have it. Some see it comparable as a mission statement or a reflection of purpose of your organization but for sure the foundation of your strategic planing.

You've got to be very careful if you don't know where you are going, because you might not get there.

Yogi Berra

Make sure that you understand that depending on your perspective the True North can be for everyone different based on their point of view. But in Lean Management or Operational Excellence with True North you define a specific set of ideals that are providing a compass for your organizational change. No matter if you talk about strategy, processes, culture or geographical challenges.

With the help of the True North principle it is clear to what you should do and not what you can do. In the Lean World you might have heard about the term of the Ideal State the Ideal State defines a state of perfection in your complete organization. Thinking about processes - a process is then as simple as possible when you can’t take anything more off it. This is state you are aiming for.

The continuous improvement process has no end, and you will constantly drive the PDCA cycle over and over again - only the starting point shifts to the next level.

But no matter what, it is like sailing on the ocean, without navigation you won’t reach the shore. The ironic part of it: you will never reach the shore - speaking of being done improving. True North is a way of running your organization not some final defined target state. It describes your daily practice of beating yesterday.

Target Agreement

A Target Agreement is a management technique where employees and management together reach an agreement on how achieve the organization’s targets.

A Target Agreement is a management technique where employees and management together reach an agreement on how to achieve the organization’s targets. It thereby consists of two key elements:

The TARGET

and the ACTIONS

Targeted state including the measures taken to achieve the set targets. Think about KPIs - a combination of quantitative measurable targets and an action plan following the PDCA.

Key Performance Indicator

A method of tracking or monitoring the progress of existing daily management systems.

Key Performance Indicators are measurements utilized to indicate the performance level or progress with regard to important objectives or defined success factors within your organization. To make it short KPIs are used to track or monitor the progress of your existing daily management system.

So how do measure our progress of our organization? How can we define what type of indicators we should use and what they tell us about the current state of our processes? And so on…

These are just some questions that might rise when thinking about implementing KPIs in order to better understand your organization and define a path to go for improvements. What processes are truly adding value to the final product or service the customer is willing to pay for and what is just waste?

Before you start implementing KPIs in your organization a helpful way is to categorize KPIs in two ways: leading and lagging indicators.

Leading Indicators

Leading Indicators are Performance Indicators that are tracking your process. So these are real time figures showing you deviation to given standard or if there is something missing in order to produce your goods or services. They have a real time effect on your delivery performance. The fun part with leading indicators is that you have real time results why it can also take months for a report showing how your organization is doing in general.

For example, talking about injuries, when an operator is involved in an accident during a process step. This incident will be documented on an incident rate report of the organization, for e.g. factory. So when you think about it you recorded an incident after it happened. This is a necessary process in the majority of organizations due to governmental regulations and safety laws. The question to ask is now what do you do with this information? Do you really know what caused it? The information is quite old. This is why the incident report is not a leading indicator but a lagging indicator.

Lagging Indicators

As just mentioned Lagging Indicators are result-oriented, because of this they are shown after something happened. With lagging indicators you react after an amount of time as you are reacting on something that is already in the past. Coming from automotive this is typically a customer claim in the field, you will have a lot of work to do to find out what actually caused the failure, if no proper traceability is installed. Attention: With those failures it is often miss leading that through assumptions symptoms are fight that are not real. Everybody from Task Force Managers to shop floor firefighters knows that. In this case you are not adding any value nor do you implement a sustainable solution.

Having this two categories in mind we can say that the majority of KPIs are lagging indicators. This is not only in the field of manufacturing. The most miss leading assumption thereby is that with Lagging Indicators we get the most information.

But openly asking - isn’t it better to prevent the accident before it happens? This is absolutely speaking for Leading Indicators - and by focusing on Leading Indicators your focus in daily operation will shift to your process and not the overall outcome. In fact: when focusing on improving your process as a side effect the overall outcome will increase automatically.

Where to start with KPIs?

First things first - don’t overdo it!

Start to ask yourself what is your daily business? What processes are constantly and repetitive in use? The same principle with Gemba Walks go to your employees and talk to them - ask what is doing well and what not. What can improve their work?

The situation can be daily checked with line reviews or the so called meeting cascade. Where on the lowest level with the shift hand over performance KPIs are reported and issues during the shift are addressed. This figures are then visualized on the e.g. “Cell Board” near the outline of the cell itself. Typically if you have an U-Shape Layout at the spot of raw material and finished goods.

If something goes wrong latest after one shift the focus will be on this process. This automatically prevents new incidents from having a threatening impact. This is the advantage from getting things done right away or afterwards when the game is already over.

Finally to bring it in a nutshell, try to bring your KPIs from lagging into leading. This will shift the focus on the whole organization towards daily processes and improving them with the help of daily Kaizen activities. Measuring the process constantly in real time gives you the opportunity analyze trends and adjust processes to be ahead of the game instead of being surprised by the market.

Analyze your data existing decide what to go for. Implement your KPIs and make sure they go hand in hand with a meeting cascade. This ensures the consistency of data used and that they are actually used to trigger actions. Based on the KPIs you will be able to drive focused improvement actions through shop floor management, visual management, standardized work and structured problem solving.

Visual Management

How visual management can help you to keep the overview of your operations.

Hej there! Great to have you back! In this article we want to show how visual management can help you to keep track in daily operations.

Generally speaking Lean Management can be seen as a clearly organized workflow that defines the way your organization should work following given principles. Above all principles existing lies to avoid waste in any kind following the 5S Principle as foundation: 1 Sort out 2 Set in order 3 Shine 4 Standardize 5 Sustain.

For a clear visualization of running process in your organization, cleanliness and orderliness is the main part of it. Clarity of your processes on the shop floor is the foundation for all lean manufacturing activities. Having the clarity the implementation and maintaining of visual management methods will guide you to a real state of flow.

In the following we want to describe key basic visual management elements that every production, following the lean principles, should have.

Boards, Notes, Infographics, Brochures and even Movies

Don’t panic and try to explain all those Japanese words it works well without being too technical. Many instruments of the Lean Manufacturing Methodology are very useful to raise the awareness of your employees about lean management. Once implemented and continuously driven by the management the incentives are there to drive daily improvement measures.

The target with visual management and those methods are all the same:

Create transparency

Visual representation of procedures processes and services

Making problems (or bottlenecks) visible

Kanban Boards

Kanban can be literally translated as “card” in the context of a production system. No matter what processes you have, it all starts with a customer’s order. The Kanban card is then used to inform upstream processes about the need of materials, pre-assemblies or process steps. This automatically leads to a cycle that triggers itself through the complete value creation chain.

This is the so called pull principle the advantage if this principle is that, in best case, you have no work in progress which means you have no stock of semi finished goods built up, because only what the following process steps need is produced.

A3 Reports

The term A3 Report comes simply from the size of paper which is used for the documentation of the report. The structure itself follows the PDCA methodology.

The A3 Report is the representation of a problem to be solved. In this case the responsible person from the quality department takes the A3 Report, starts the problem solving actions and follows a systematic structure that makes it possible to describe the effects that are currently leading to a deviation from the standard. Using the A3 only makes sense when you don’t know the root cause yet. If you already know the root cause don’t waste your time. Fix it and go back to normal.

Andon: Lean management with boards and ripcords.

Andon again a Japanese word meaning “lantern”, at least in the context with lean manufacturing. It is a visual aid that is there to draw attention to problems on the shop floor when machines or processes are causing defects or simply stop working.

You might think you have seen them all by walking through production and seeing all those PLC signal lamps indicating green or red, but there is so much more. Just have a look at the Andon article.

Just want to name administration, maybe there is nothing to indicate, but when you think about a document that is needed in a different department, waiting for this is one of the TIMWOODS MUDA. The time waiting is probably the best indicator to start with lean admin activities.

Andon Cords - Please pull the rip cord in an emergency!

Andon Cords are rip cords or a simple button straight at the operation on the shop floor that gives the operator in the process the possibility to instantly stop the line when problems or defects occur.

Andon Boards

Andon Boards are displays or nowadays mainly TV screens that are showing the actual status of the manufacturing line e.g. PPM, down times, etc. Typically it is automatically feeded by the machineries of the production line. With the standard defined color indication everyone sees if they are doing great or not so great. In the second case an automated alert to supervisors or maintenance is triggered.

You see there are many possibilities, but the target is always the same. One hint at the end: Make your boards, infographics or brochures as simple as possible! (or just use mine ;))

WHY? As with processes > it is only a good process when you can’t cut anything more away from it. In other words: What is the value you get from something that nobody understands?

If you take the principle of visual management seriously it will help you to bring all processes in your organization to live.

Set up time reduction

Set up time reduction. Nice and simple.

First things first. In order to reduce set-up time the set-up process itself must be observed and analyzed (e.g. by using the EMIPS - eliminate, minimize, integrate, parallelize or synchronize - methodology).

After you have analyzed the process make sure you write down all identified kinds of waste. Try to define the ideal state of the new procedure. Only after verification through testing of the new procedure make it a standard and implement it in your TPM framework. By doing so your operators are now responsible for the new set-up procedure, assumed that your operators are properly trained.

The whole focus on set-up time reduction comes from the customer requirements to manufacture a higher variety of goods in smaller batches. In order to meet those requirements set-up or change over must be kept as short as possible.

But let us go a little bit more into the details.

The pure set-up time is defined as the time needed to change from the last part of a batch to the first part of the following batch.

The set-up includes all activities needed, preparation, action on side and adjustments needed. By doing this you automatically differentiate between so called “external” and “internal” activities.

The following steps should help you to make it easier to reduce set-up times

1 Classify each part of the set-up process to either internal or external. Internal steps are those that only can be done while the production is or has to be inactive. External steps are done without interrupting production.

2 Convert internal steps to external ones. The whole idea is to minimize the time needed shutting down operations. This is why we want to take internal steps out as much as possible.

3 Reduce the time needed for the remaining internal steps. There are for sure some steps you can not take out, for those the manufacturing has to be stopped. The whole focus is now on this internal steps and how to reduce them to an absolute minimum. Here the SMED methodology (Single Minute Exchange of a Die) can help. Too find out more you can read here.

4 Eliminate adjustments. Last but not least try to get stable process parameters. With effective process control in place you can get rid off adjustment activities.

A Pareto Diagram can be useful to prioritize the setup time reduction activities. Don’t start everywhere at the same time! Start with the biggest loss and you will see over the time how it will change. It also gives you a great opportunity to see the progress that you are making on set-up time reduction.

DMAIC

Define, Measure, Analyze, Improve, Control. DMAIC is an incremental process improvement using Six Sigma methodology.

Define, Measure, Analyze, Improve, Control. Incremental process improvement using Six Sigma methodology.

DMAIC can bee seen as a data-driven improvement strategy and for sure is part, or will be a part, of your organizations SIX SIGMA quality initiative. DMAIC is an acronym for: Define, Measure, Analyze, Improve, and Control.

DMAIC is a cyclical process such as the PDCA is. The reason to go for the DMAIC is to strive for the best result possible with a structured approach.

These process steps are:

DEFINE: the customers and their CTQ (Critical to Quality) and the core process involved.

Who are your customers?

What are their requirements for products or services?

What are their expectations?

Go for a value stream and map the process flow through the complete business process

MEASURE:

Define a plan on how to collect data from your core process

Go for different sources of data in order to be as specific as possible on defects and metrics

ANALYZE:

While analyzing the data along the process map make sure to identify the real root cause of defects and

point out opportunities for improvement

Compare shortfalls with the results of customer surveys

Determine gaps between targeted performance and current performance

Prioritize potential improvement measures

Identify variation and their source

IMPROVE:

Kaizen Workshops

Target is to improve the current process in a simple and effective way

Develop a prioritized action plan

Do it!

If you want a structured approach, just read our PDCA article.

CONTROL:

Stay tuned on your process improvement measures

Make sure that they stay on track

Prevent falling back to the “old way”

In the end, when you are in charge, require the full documentation. Make sure that everything implemented is well documented and a clear monitoring is installed that deviation can be fast identified.

Having or installing a sustainable problem solving culture in your organization will be key for the future. Make sure to institutionalize problem solving or a kaizen culture through training, training and more training.

Turtle Analysis

“Turtle Diagrams” are an effective tool to understand the processes from both a managerial and workforce perspective.

Turtle Diagrams are an effective method to understand the processes from both a managerial and workforce perspective. These diagrams can also be used to identify gaps in the organizations structure and further develop organizational procedures. From these activities further measures can also be developed for efficiency improvement.

How to use Turtle Diagrams

We will go through the diagram step by step:

INPUT:

Enter details of actual process inputs such as raw material, requirements, information, documents, etc.

PROCESS:

Enter your management process.

OUTPUTS:

Enter your expected or defined output of your process. This can be finished goods, products, records, documentation, etc.

CONGARTS you already described your main process. Now we will complete it with details.

WITH WHAT:

This is asking for materials and equipment. Enter details of materials, components, machinery, test equipment, software, etc. all you use in the process.

WITH WHO:

Resources and competencies. Enter human resources requirements, including qualification, competencies and training requirements or restrictions.

HOW:

The how goes for the supportive processes, procedures and methods. Write down linked processes, pre-processes, supportive processes, instructions, procedures, standard work described, etc.

WHAT FOR:

Key Performance Indicators. Enter the targets, KPIs, performance measures, etc. to measure effectiveness and efficiencies.

Example of a Turtle Diagram

How to use the Turtle Diagram for auditing

When running an internal audit, you can use the Turtle Diagram to understand the relation between input and output for the audited process or activity. In order to get full advantage of the audit, the auditor needs to assess not only the process itself but also the complete surrounding such as the process owner, stakeholders of the process, standard work procedures, training and qualification matrix of persons involved, as well as linked processes. Based on the Turtle Diagram Layout the auditor has a guide to follow through the process audit.

Running the Turtle Analysis

When talking about quality management, process analysis is a key part of daily business. With the Turtle Analysis and the resulting Turtle Diagram you will have the chance to describe processes in a simple and clear one pager. The summary of this one pager is the description of the most important process characteristics. This overview can then be taken to identify risks and weaknesses of the process and build the framework for upcoming quality audits.

The Turtle Diagram gives a clear picture of the links between two process steps or different processes. As usual in manufacturing environment the output of one process step is the input of the other. This can be made visible with the the Turtle Analysis. You starting point is then when interfaces do not run smooth or e.g. important information is lost during hand over phase.

In addition after a Turtle Analysis or audit with the diagram and identified risks and weaknesses you can define specific objectives to be addressed. As mentioned above you can steer and control your improvement actions with pre-defined KPIs, this helps you to visualize deviations from the set course easier.

If you think you need a deep dive on one specific topic found during the Turtle Analysis, we recommend the ISHIKAWA or the 5Why methodology.

Waste

The opposite of value creating are non-value adding activities. Those can be remembered with TIMWOOD.

Waste (MUDA)

Waste or MUDA is the opposite of value creation. Waste describes all non-value-adding activities the customers are not willing to pay for. The two main categories are obvious and hidden waste. While obvious waste can be eliminated, hidden waste can only be minimized.

When talking about waste there is no way around the 7 kinds of waste according to Taiichi Ohno most known in the lean world as TIMWOOD. Feel free to read the complete article on TIMWOOD(S) - yes you are right - where is this S coming from… keep on reading and you will see.

The 7(8) kinds of waste:

T = Transportation

I = Inventory

M = Motion

W = Waiting

O = Overproduction

O = Overprocessing or - engineering

D = Defects

S = Unutilized stuff

It is important to be aware of these kinds of waste in the list. But overproduction is the worst and typically initiates the other types of waste.

To read more in detail about TIMWOOD go here.

Pareto Principle

The 80/20 rule demonstrates that things have an unequal distribution. Out of 5 one will fly and have the most impact. With 20 percent of action 80 percent of your target state is already reached.

The Pareto Principle describes that 80% of problems can be closed with 20% of the causes. This principle is named after Vilfredo Pareto who found out that 80% of Italy’s wealth belonged to 20% of the population.

With this in mind it is worth to have a look at it.

Let us start with an assumption, according to the Pareto Principle it allows us to assume that

20% of input creates 80% of the output

20% of customers create 80% of your revenue

20% of causes create 80% of failures

20% of your employees create 80% of sales

and so on…

But before you run away now and think you have the answer hold a second. With the 80/20 rule you might tend to say that it always have to be 100 - it’s not. Make a deep analysis before making such statements! 20% of your employees can also make only 20% of sales or 60%. So before you fire 80% of your employees keep in mind that the Pareto Principle only gives you an idea on the distribution.

The whole idea behind it is that most things in life are not distributed evenly!

When we talk about value adding activities and the final product is 100% What is with all the necessary tasks, that are not adding any value to the final product but have to be done to run the company.

Or think about failures and finding the root cause, where to start to take actions? This is great when you think about a Failure Pareto and you want to satisfy your customer as quick as possible. Of course you are focusing first on the most failures and most of the time - not always - the other failures will disappear as well.

But most important of all, your customer gains trust in you that you have the competencies to do the job.

The key point is that most things are not in a 1/1 actio = reactio relationship.

So what can we use it for this 80/20 rule?

The Pareto Principle in first place supports you on realizing that most of the outcome are based on a minority of inputs. This means:

20% of input creates 80% of the output > try to reduce those non value adding activities

20% of customers create 80% of your revenue > install a key account manager that the customers knows he/she is important to your company > your customers success is your companies success

20% of causes create 80% of failures > Focus on fixing those failures first

20% of your employees create 80% of sales > get those employees a reward

We could continue on and on. To bring it to the point > focus on the 20% and not on everything at the same time.

Some examples that might help you for a better understanding:

Instead of spending a whole night to prepare a presentation and thinking about where to start > focus on one topic and do it. You will get a feedback anyway during the pitch. This feedback gives you the chance to take it and improve it.

Instead of focusing on one solution that might be the best and go through all the details. Make a list of three and go through the pros and cons with your colleagues that probably know the topic better anyway and based on their opinion make a decision with what to go on.

Maybe this examples are nuts for you but we want to emphasize that you should focus only on the important 20% and forget - for the moment - the other 80.

Last but not least - the Pareto Principle is not a law of nature it is a guideline to steer your focus and to save time on problem solving or simply getting your job done faster.

FMEA

The method of the FMEA - Failure Mode and Effect Analysis has been used for years in the automotive and manufacturing industry.

Failure Mode Effects Analysis - FMEA

The method of the FMEA - Failure Mode and Effect Analysis has been used for years in the automotive and manufacturing industry.

The risk analysis framework has been applied in a wide range of industrial sectors. The first areas of application were traditionally in product development. Based on this the integration of the production process planning and the production. In the automotive industry, the joint creation of FMEA for products and processes by Today customer, supplier and subcontractor are a natural part of a cooperation.

The user is guided through the "10 Steps to Creation of the FMEA".

Step 1 - Review the process

Use a process flow chart or an already existing value stream map to identify each part of a process

List all process steps in a FMEA table

If you think the list gets too long it might is. Use this chance to split up the process and cut the elephant. It makes more sense to work on smaller parts of the process instead of getting lost in the woods.

Step 2 - List potential failures

Review all existing data and documents that can give you a hint about each component that can lead to a failure

After having a complete list try to cut it down and to combine the parts of the initial list

The chances are high that you will identify several potential risks of failures for each component

Step 3 - List potential effects of failures

The effect is the outcome of a failure on the finished good or a process step

It is common that not only one effect will occur for a single failure, don’t be suprised

Step 4 - Assign the level of failure to risks

This is based on the consequences for each failure

Think about the ranking as the worst impact that it can have

Step 5 - Assign the possibility of occurrence

How high is the possibility of occurrence

What impact will it have if occur

Step 6 - How can it be detected

What are the chances that you will detect the failure before occurring

Step 7 - Calculate the RPN (Risk Priority Number)

Severity (S)

Severity x Occurence (S x O) = criticality

Severity x Occurence x Detection (S x O x D) = RPN

Step 8 - Define the action plan

With the decision making process followed by the prioritization from the RPN (Step 7) focus on the topics with the highest RPNs

Follow a classic action plan by defining who will be doing what till when

Step 9 - Take action

Get things done!

Implement the defined improvement actions

Follow the PDCA principle

Plan - done

Do - right now

Check - Step 10

Act - loop starts over

Step 10 - Re-evaluate the RPN

Time to check on the impact of your actions

Re-evaluate each potential failure identified and determine if the improvement measures have an effect or not

If not follow the PDCA and start over with step 8

The FMEA is linked to all CIP and Kaizen activities - there is always something to improve.

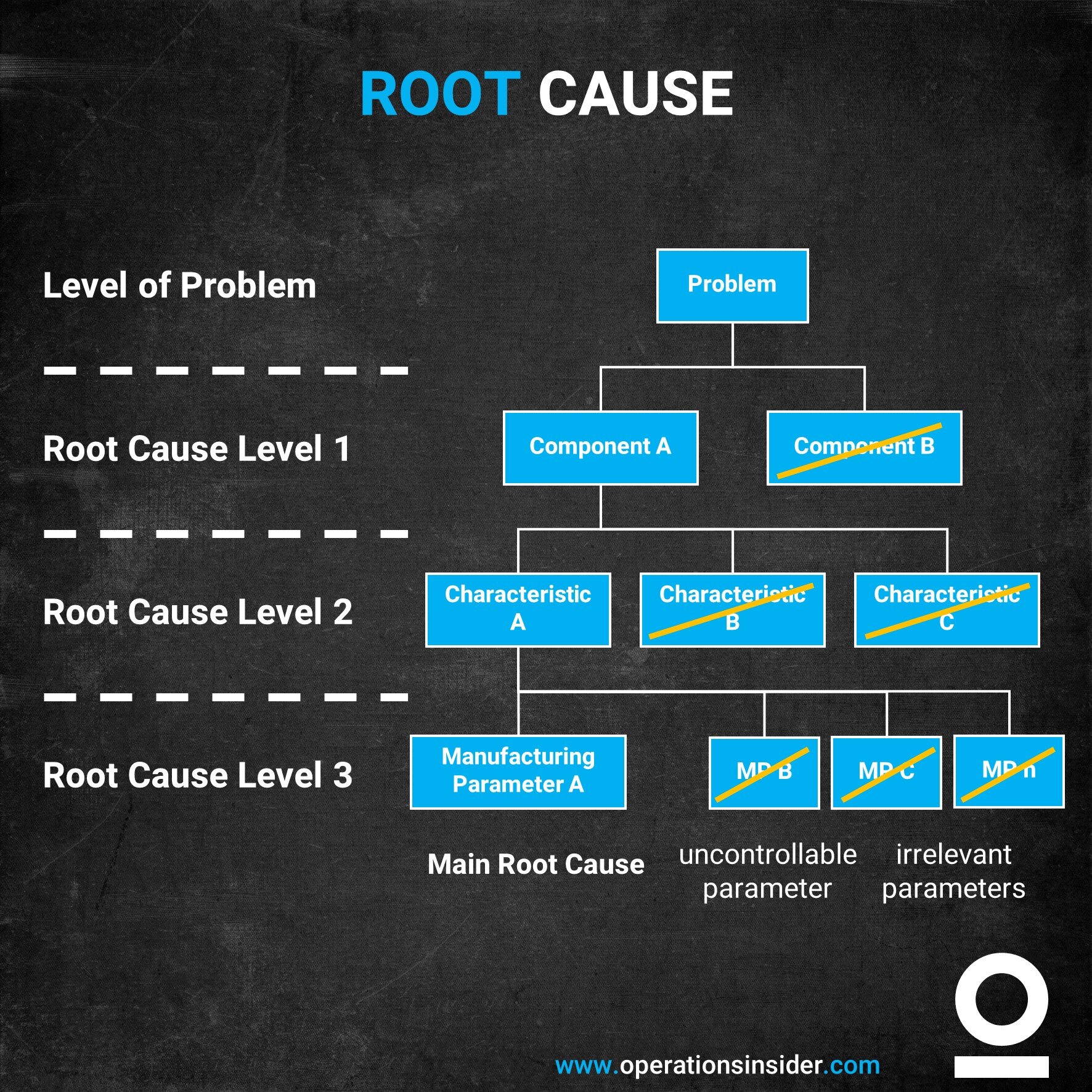

Root Cause

The ultimate reason for an event or condition.

The Root Cause Analysis brings you to the ultimate reason for an event or condition

Methods used in the root cause analysis help you to identify the actual causes of defects or problems in your goods or processes. The whole idea behind a root cause analysis is to understand and get rid of the source of the problems and not to fight the symptoms. Thinking about quality management the Root Cause Analysis is a big part of it and has an impact on Six Sigma and 8D processes.

The root cause analysis is in demand when problems can no longer be solved with pure empirical knowledge (e.g. known products are used in new operating conditions and cause problems there).

The basic idea of all Root Cause Analysis methods is first of all to describe the problem (symptom) as precisely as possible, to limit the potential sources of the problem and then to systematically follow the error path. A distinction has to be made between purely theoretical analyses and experimental root cause analysis.

Known theoretical methods are the 5-Why question technique and the 6M method (Ishikawa). These methods, however, often suffer from the limitation to consider complex problems insufficiently. For example, it is impossible to identify combined root causes.

For complex problems, Vester's system analysis shows very good results in practice. Using the so-called intensity relationship matrix, expert knowledge is systematized and thus contributes to new approaches.

The area of root cause analysis also includes experimental designs that have the goal of eliminating a problem. A distinction must be made here between problems resulting from the production and assembly process and those resulting directly from the components or combinations of components. One of the well-known methods in this area is the component exchange methodology, which represents a methodically and statistically proven way of eliminating problems caused by components.

Apply Root Cause Analysis methods to your quality problem.

6M methodology (Ishikawa)

Vester` intensity relation matrix

Problem identification and identification through statistical product analysis in ongoing production through a practically established multi-stage problem-solving approach.

Root Cause Analysis

Ergonomic Workplace

A work place that takes into consideration most of the ergonomic aspects such as the operator’s height, range and reach.

An ergonomic workplace is a work system that considers the ergonomic aspects of an operation and the operator such as the operator’s hight, range and reach with the goal that the operator does not need to bend or turn.

The ergonomic workplace goes hand in hand with the work improvement.

Definition and purpose

Reveal waste increasing cost and not adding value.

Find waste in the movement of workers, eliminate/improve, pursue net work adding value.

Worker Movement

Lean Manufacturing and Ergonomics may have different roots and directions but together they can complement each other and define a more efficient and safer workplace.

One of the best person known for focusing on productivity and efficiency in manufacturing processes was Henry Ford with the invention of the modern assembly line. Ford really was focusing on eliminating waste and to cut down unnecessary costs in relation to the manufacturing of his cars.

Toyota is one of the best known companies that has stretched to the maximum the idea of Lean Manufacturing and is now holding the pole position when it comes to the reputation according the elimination of “waste”.

By looking at the Lean Model as well as Work Ergonomics, you clearly see the necessity of both practices in the industrial workplace, as well as observe that both can complement each other.

The 7 types of waste to eliminate include:

Transport

Inventory

Motion/Movement

Waiting

Overproduction

Overprocessing

Defects

The list of TIMWOOD is what Toyota has defined as the seven major types of wastes or non-value-adding activities. The seven wastes do not add any value to the product and the customer in the end is not willing to pay for it. Therefore it is essential to remove as much waste as possible which will have also an effect on the ergonomic workplace and furthermore on the health of the operators.

Some of these things like transport, waiting or unnecessary movement can be reduced to a limit what the operator still needs because as human being the operator is limited by his body.

The Lean Manufacturing initiatives and workplace ergonomics stepped into the manufacturing world at different times and therefore are not fully integrated. But you are perfectly advised by combining the principles of Workplace Ergonomics with Lean Manufacturing initiatives. Through a cooperative assessment and teamwork you have the chance to complement each other in making the workplace more efficient and a safer place.

Stay Connected

Ad

We want information fast and in a nutshell. We from OI recommend Blinkist* - because it’s simply the best.

* = Affiliate Link